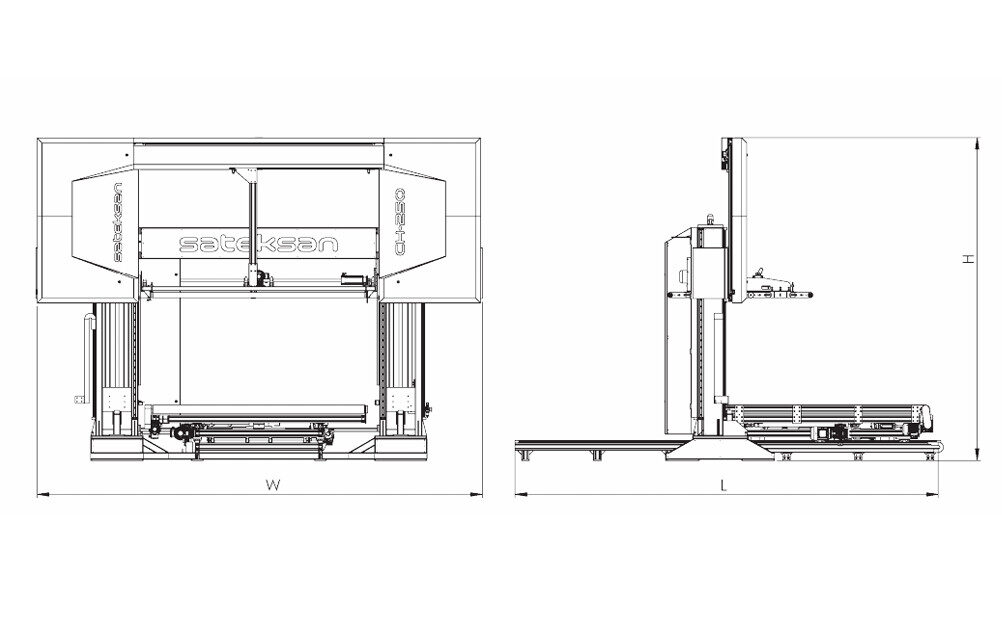

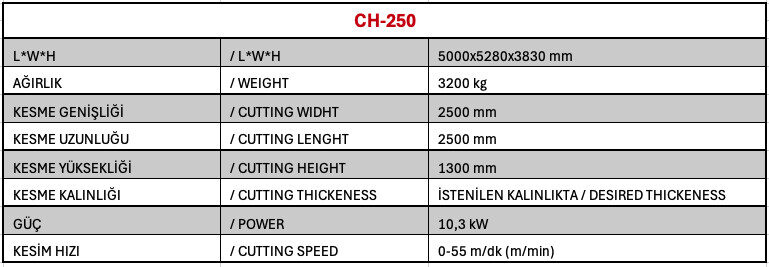

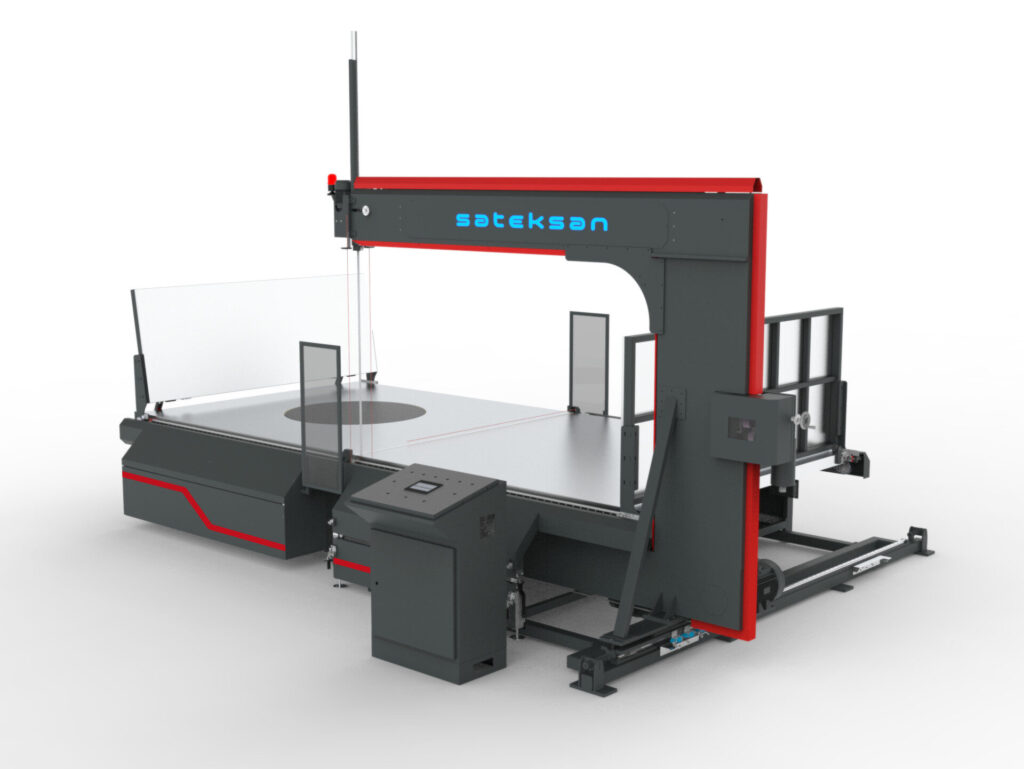

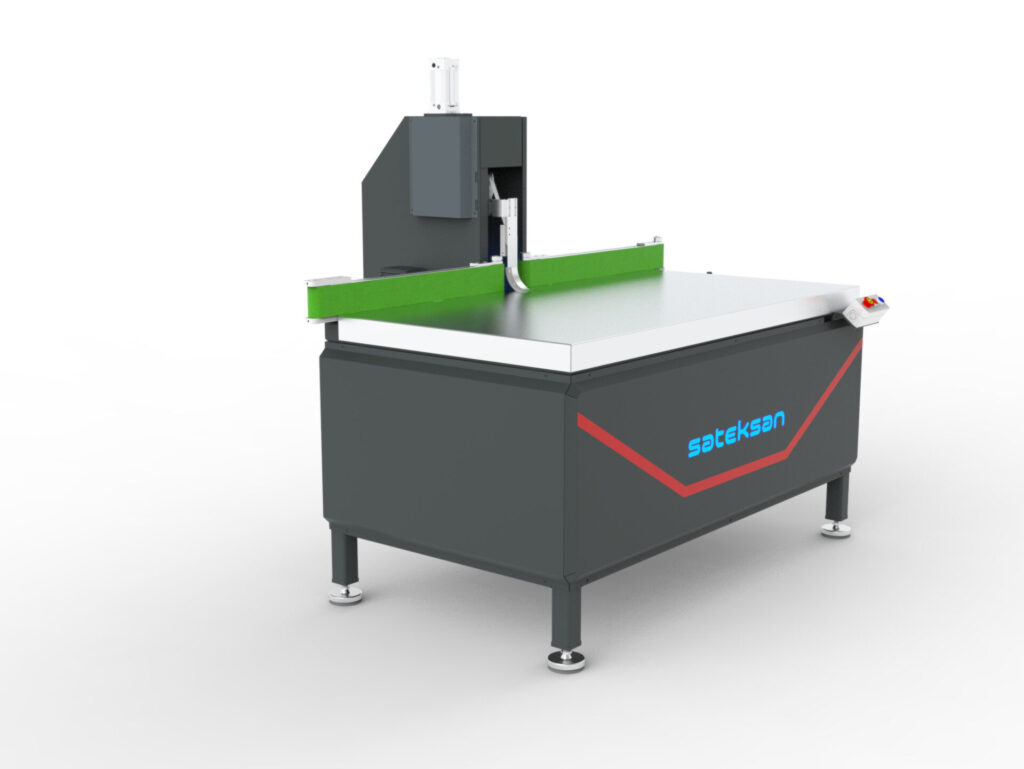

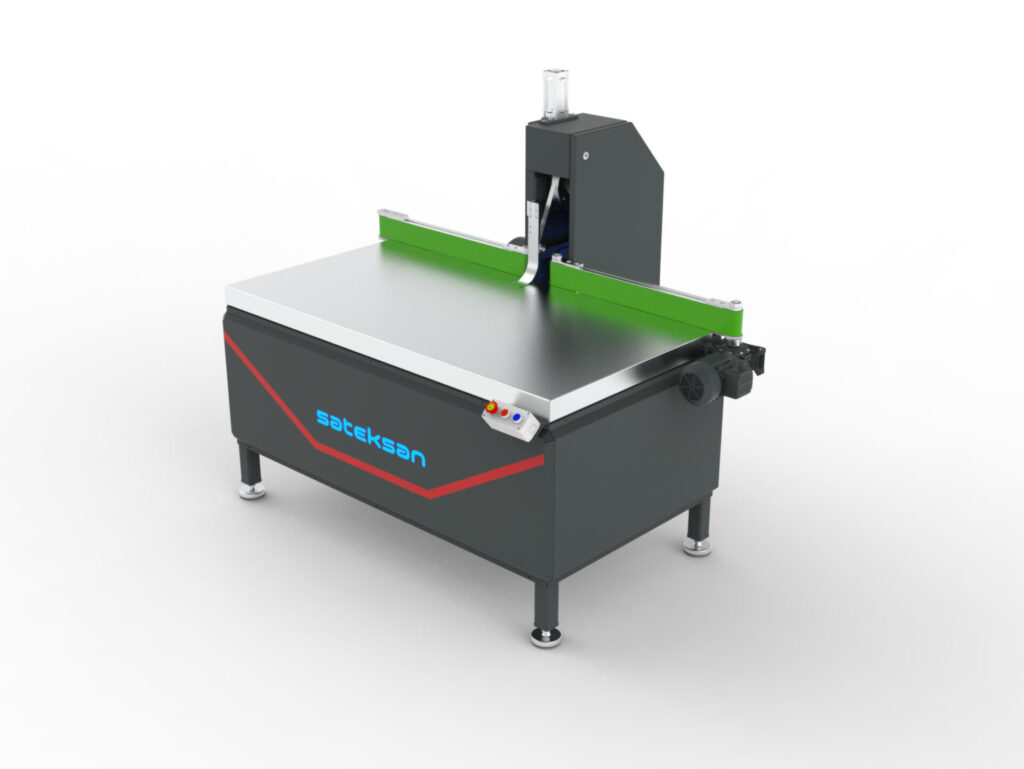

Horizontal CNC Cutting Machine

The CH-250 is a fully automated CNC foam cutting machine engineered for high-speed, precision shaping of polyurethane (PU), memory foam, and flexible materials. Featuring a 90° rotating table and ±360° blade rotation, it delivers flawless 2D/3D contours, bevels, and profiles directly from CAD designs, minimizing material waste.

Key Advantages

✔ Multi-Axis Precision: ±360° blade rotation for complex geometries

✔ Industrial Automation: BECKHOFF/SIEMENS control with intuitive touchscreen

✔ Dual Cutting Modes: 90° table rotation for 3D profiling or stacked block processing

✔ Eco-Efficient: Dust-reduction system + energy-saving motors (4–12 kW)

✔ Strong Build: Aluminum alloy pulleys + reinforced steel frame for non-stop production

- Mattresses: Pillow tops, toppers, hybrid layers

- Automotive: Seats, headrests, acoustic insulation

- Packaging: Custom foam inserts for fragile goods

- Specialty: Architectural elements, medical supports, props

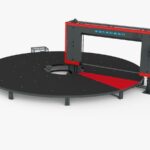

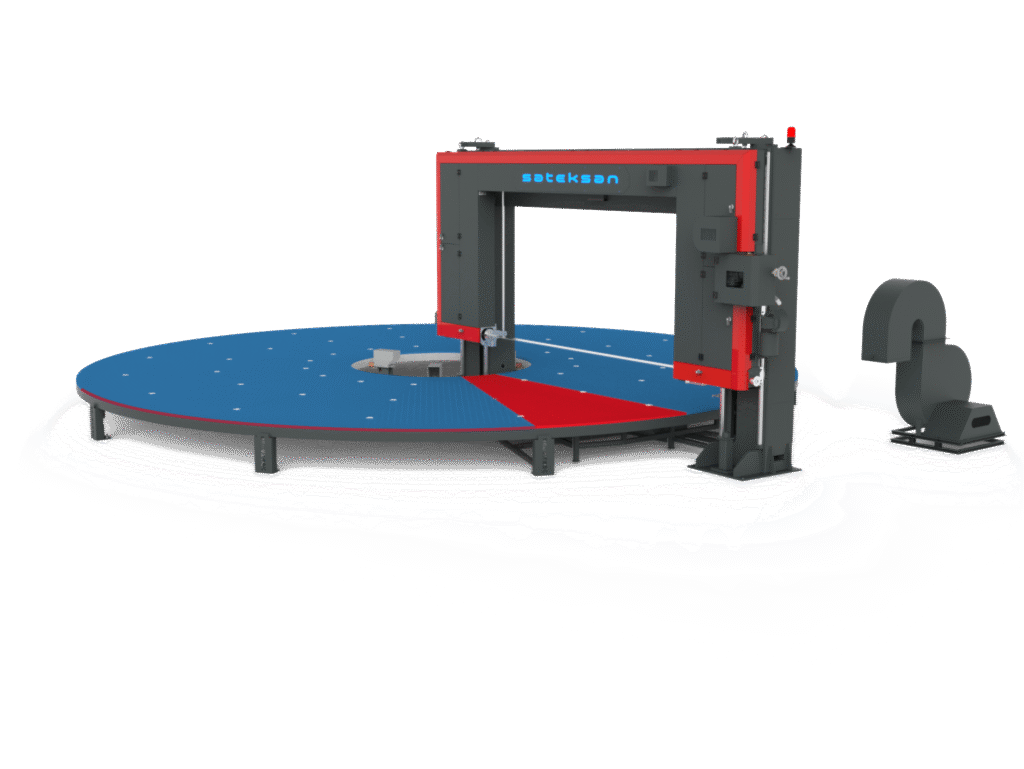

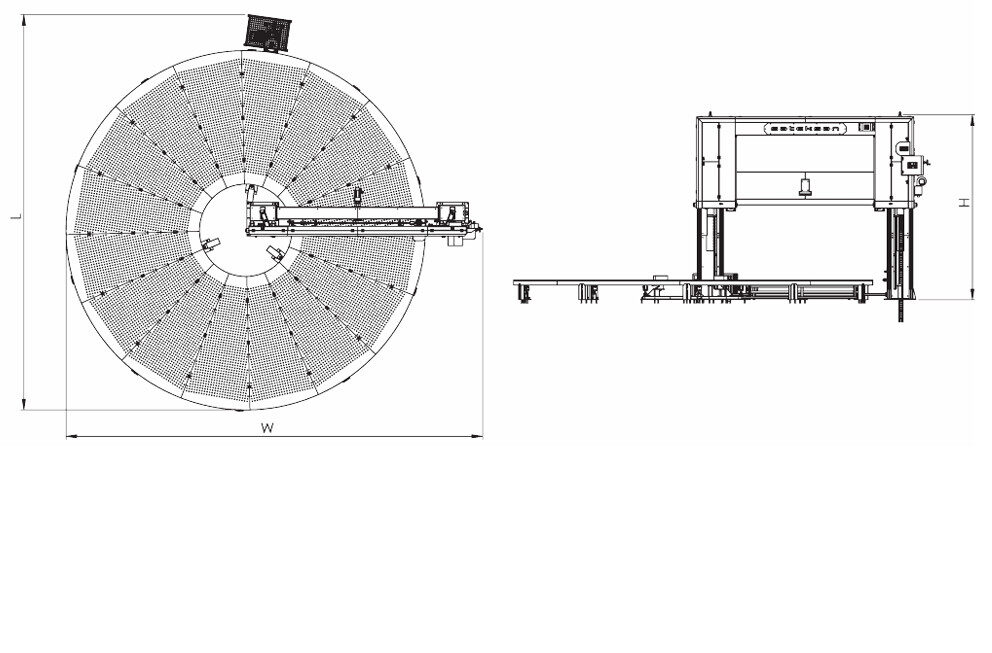

Carousel Machine

The CR-700 is a high-speed horizontal foam cutting machine featuring a powerful rotary vacuum table for precision slicing of PU, PE, and memory foam blocks. Designed for mass production, it delivers consistent thickness accuracy (±0.5mm) while processing up to 60 mattresses/hour.

Key Features:

✔ Turbo Cutting: 60 m/min max speed with synchronized conveyor

✔ Smart Thickness Control: Programmable slicing from 10–500mm

✔ Vacuum Stability: Auto-adjusting suction prevents material slippage

✔ Modular Design: Compatible with quilting/packaging lines

✔ Low Maintenance: Self-lubricating components for 24/7 operation

Industries Served

- Mattress Manufacturing: Toppers, base layers, hybrid cores

- Furniture: Cushioning for sofas, chairs, and headboards

- Acoustic Panels: Precision-cut soundproofing foam

- Automotive: Seat padding and interior insulation

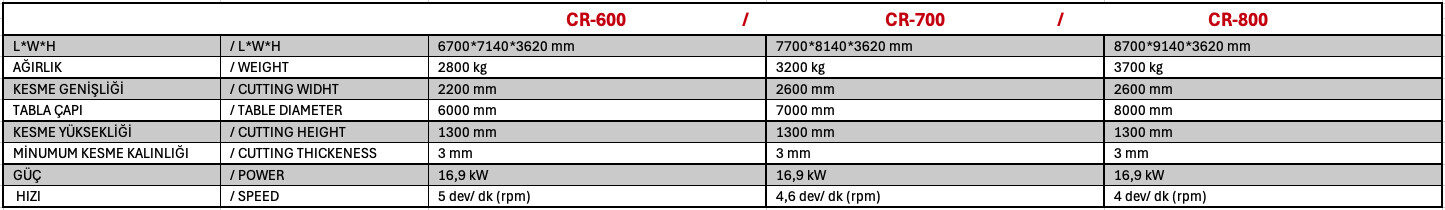

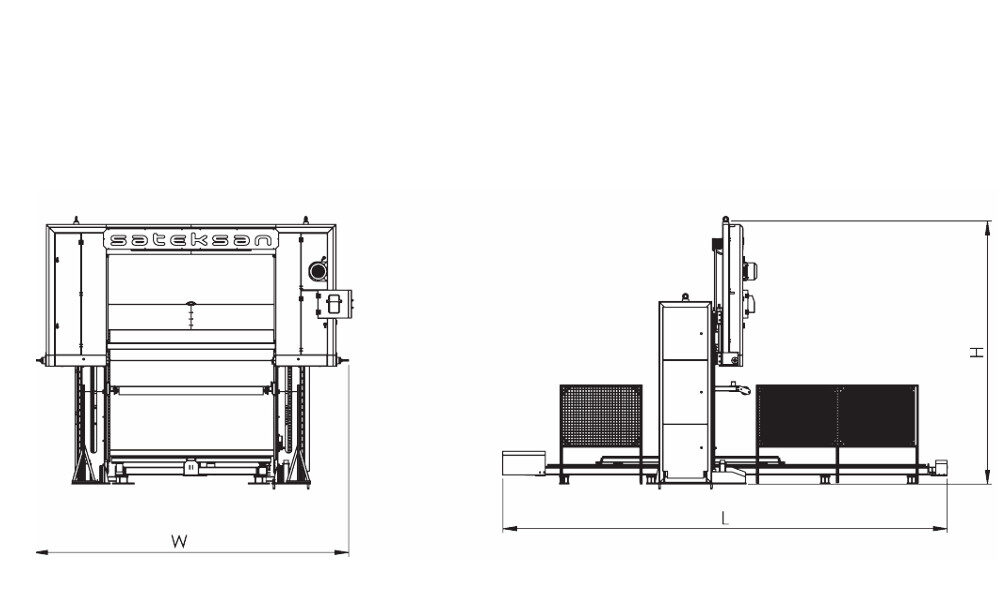

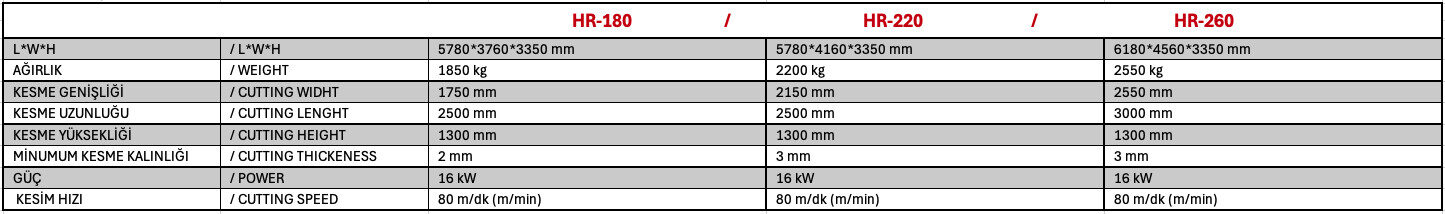

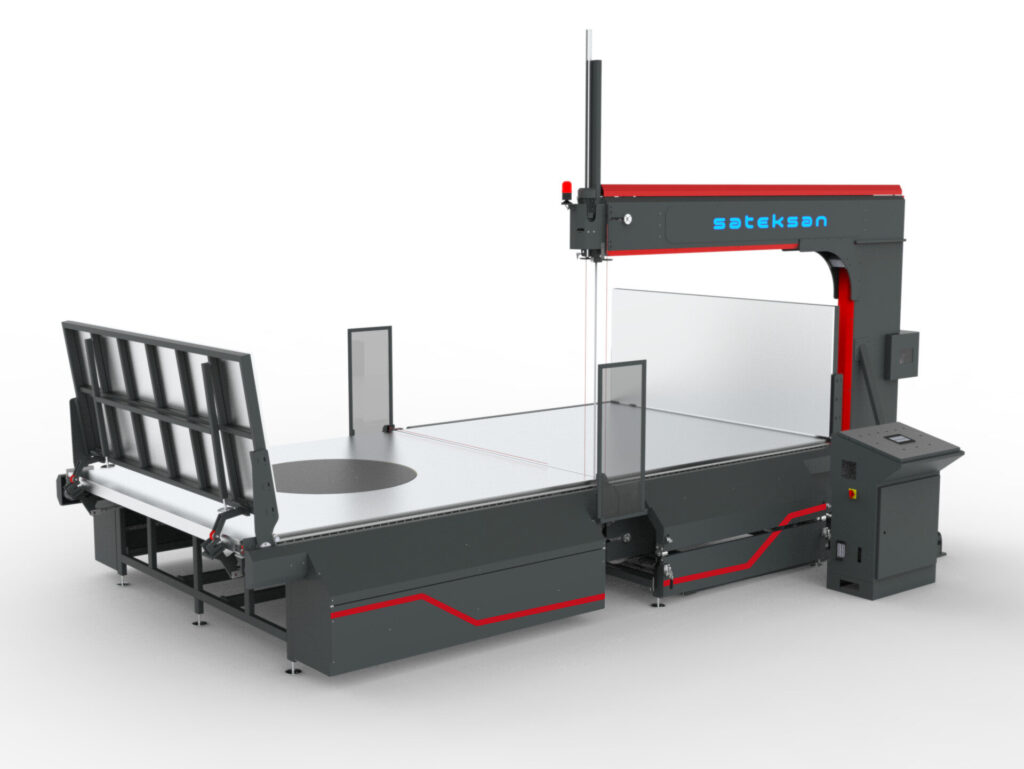

Horizontal CNC Cutting Machine

The HR-220 is a high-performance horizontal splitting machine engineered to cut 20+ foam types with micron-level precision. Its advanced vacuum table and servo-driven band knife handle everything from PU rebond foam to medical-grade XLPE, delivering uniform slices for industrial-scale production.

Key Features:

✔ Multi-Material Compatibility: Processes PU, memory foam, EVA, neoprene, latex, and more

✔ Smart Angle Adjustment: Motor-driven -2° to +8° tilt with real-time touchscreen feedback

✔ Industrial Automation: Siemens PLC + Lenze servo drives for flawless cuts

✔ Self-Maintaining: Integrated grinding and dust extraction (290 m³/h)

✔ Dual Operation Modes: Manual control or fully automated program cycles

Industries Served

- Mattress Manufacturing: HR-PU, viscoelastic foam layers

- Medical: XLPE for orthotics, neoprene for braces

- Automotive: CMHR-PU for seats, acoustic foams

- Packaging: Custom EVA/Polyethylene inserts

- Industrial: Reticulated foam filters, PVC signage

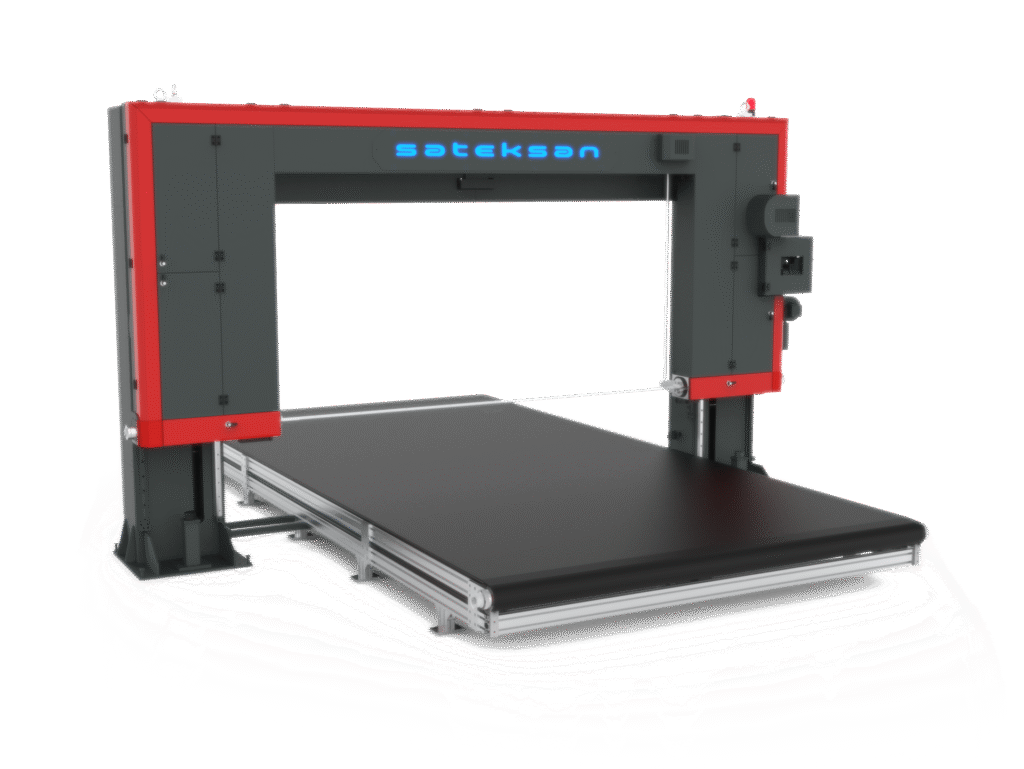

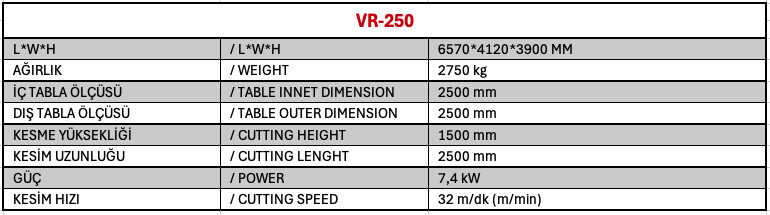

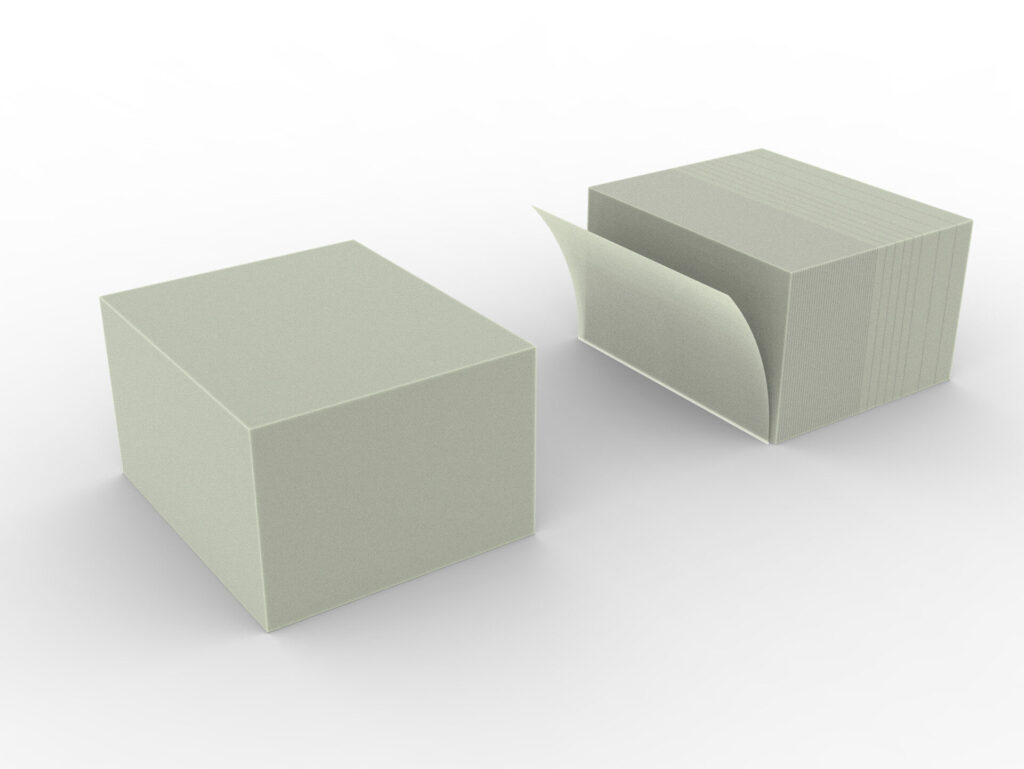

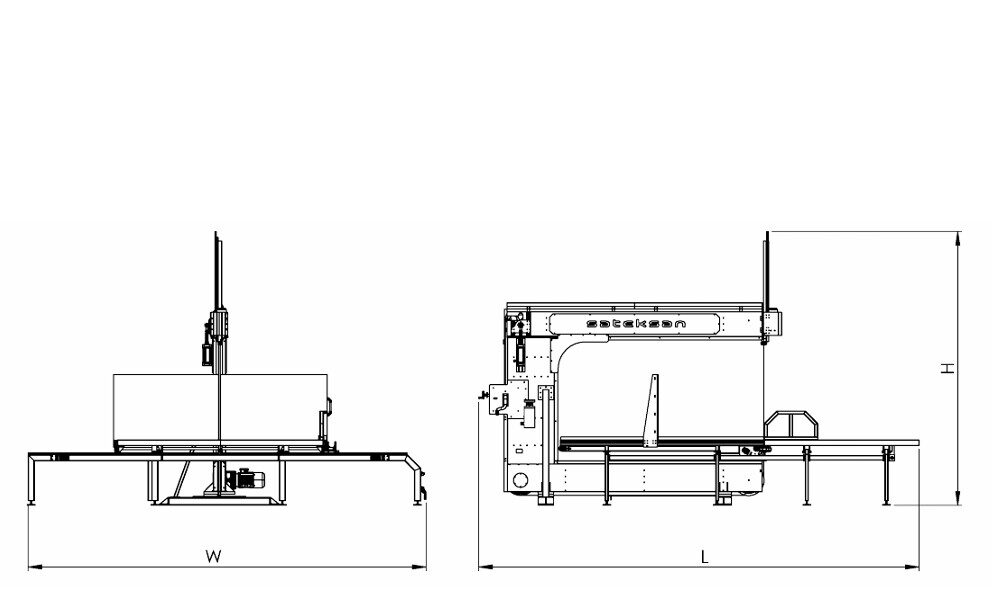

Automatic Vertical Cutting Machine

The VR-250 is an advanced automatic vertical cutting machine engineered for high-precision slicing of polyurethane (PU), memory foam, latex, and specialty foams (EVA, neoprene, XLPE). Equipped with a bidirectional knife system and Siemens automation, it delivers flawless cuts for industrial-scale production.

Key Features

✔ Multi-Material Mastery

- Processes 20+ foam types: PU rebond, memory foam, latex, EVA, neoprene, XLPE

- Ideal for medical, automotive, mattress, and industrial applications

✔ Smart Cutting System

- Heavy-duty 404mm Ø wheels with 3-phase AC motor

- 1300mm max cutting height for thick blocks

- Programmable auto-sharpening (set intervals for optimal blade performance)

✔ Industrial-Grade Automation

- Siemens PLC + Lenze servo drives for millimeter precision

- User-friendly touchscreen for real-time adjustments and preset programs

✔ Safety & Smart Connectivity

- Emergency stop buttons + safety sensors

- 2 years of software updates included

✔ Optional Upgrades

- Auto-stacking conveyor for less human intervention.

- Laser-guided alignment for complex profiles

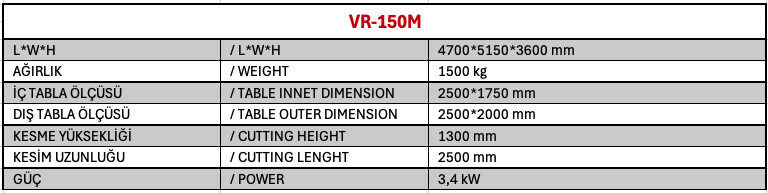

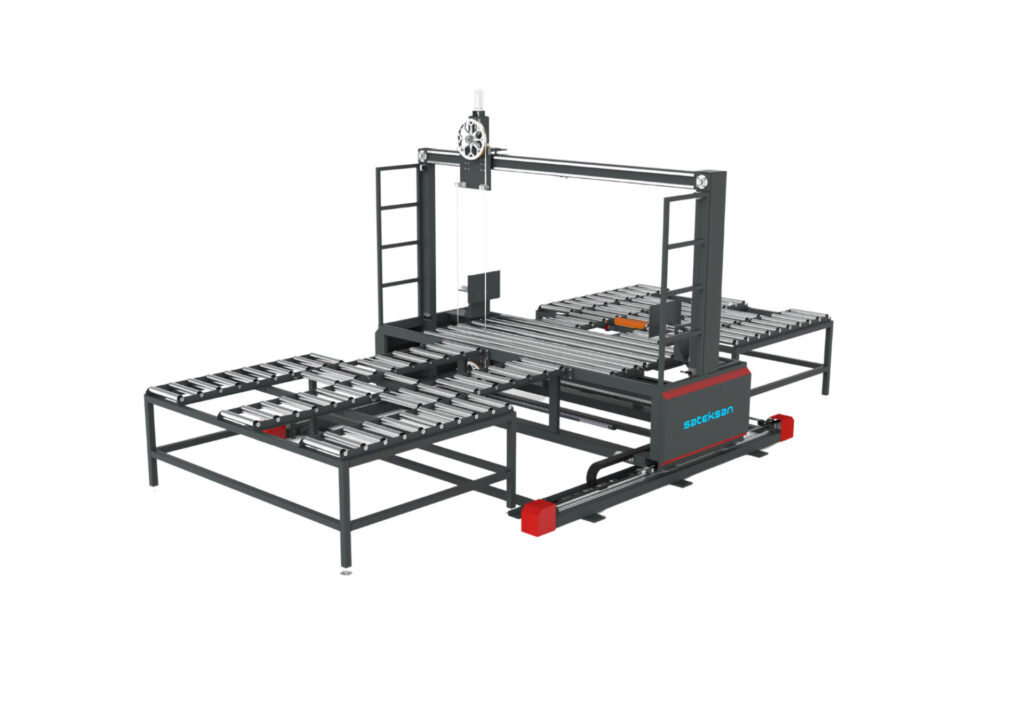

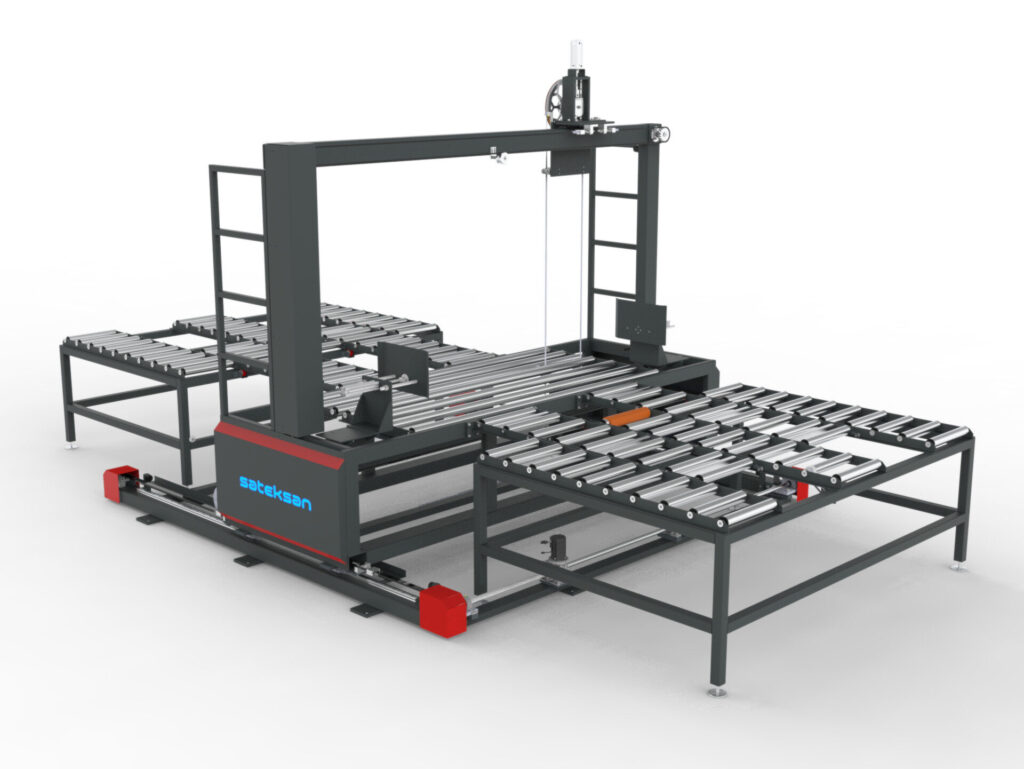

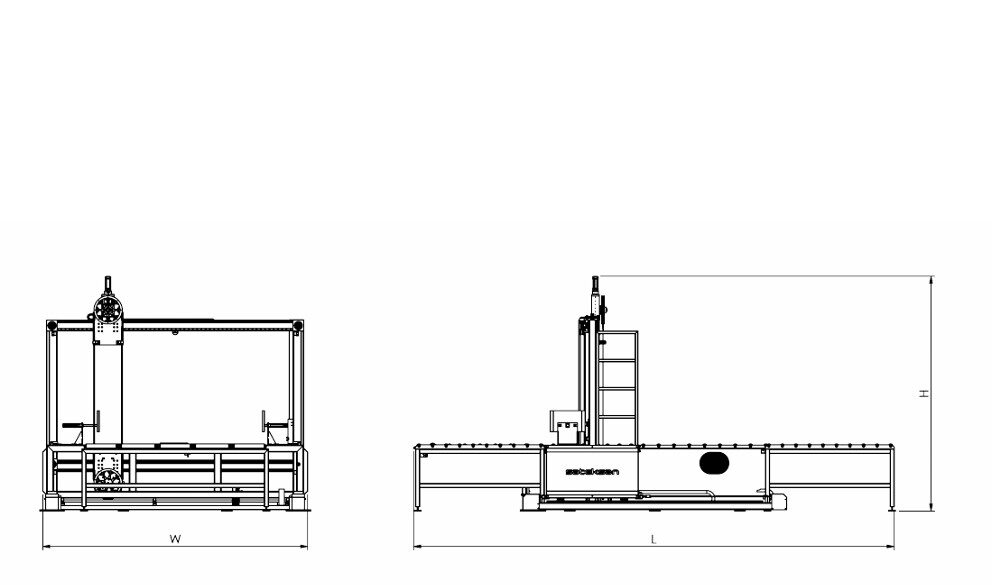

Manual Vertical Cutting Machine

The VR-150M manual vertical cutter handles PU, latex, and specialty foams with 1300mm cutting height and 404mm Ø blade wheels. Its stainless steel table (2500x2000mm) supports 1000kg loads, ideal for small-batch production. Siemens/Lenze components ensure reliability.Low investment

Key Features

✔ Multi-Material Compatibility

- Cuts PU rebond, memory foam, latex, XLPE, and 10+ other foam types

- Ideal for mattress, medical, automotive, and industrial applications

✔ Robust Construction

- Stainless steel (chrome) table surfaces

- 1000kg max lifting capacity

- Safety shield for blade breakage protection

✔ Efficient Cutting System

- 404mm Ø wheels with 3-phase AC motor

- Bidirectional cutting capability

- 1300mm max cutting height

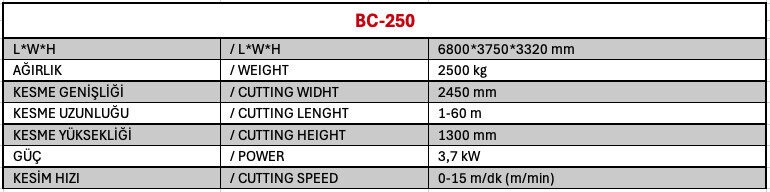

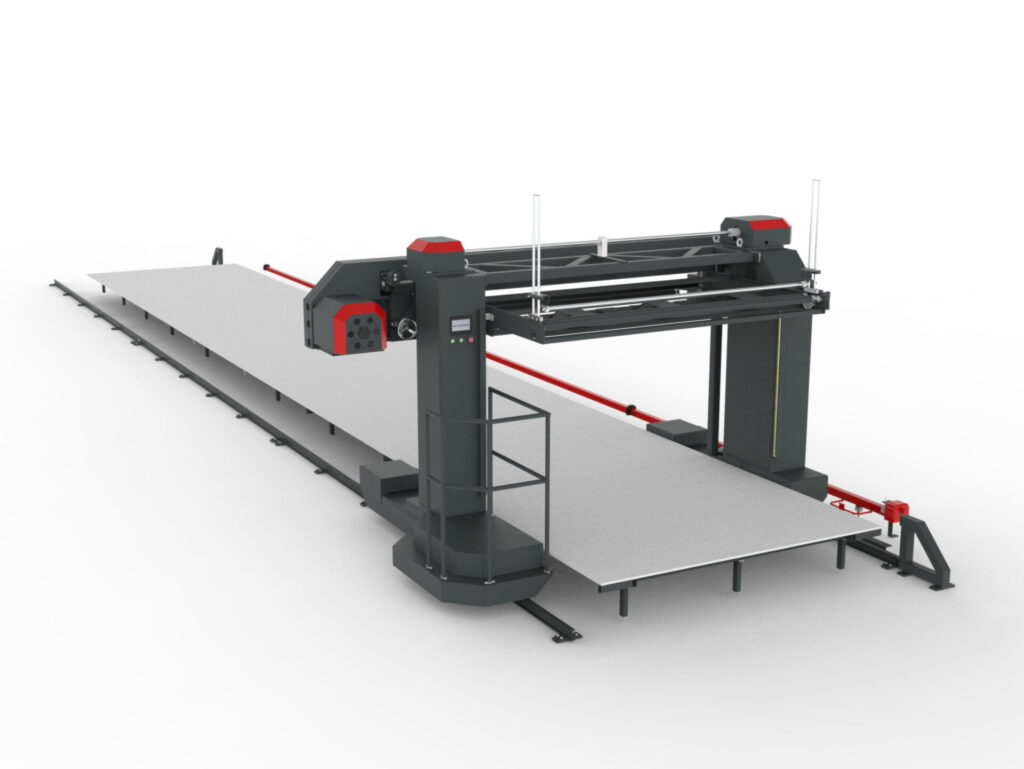

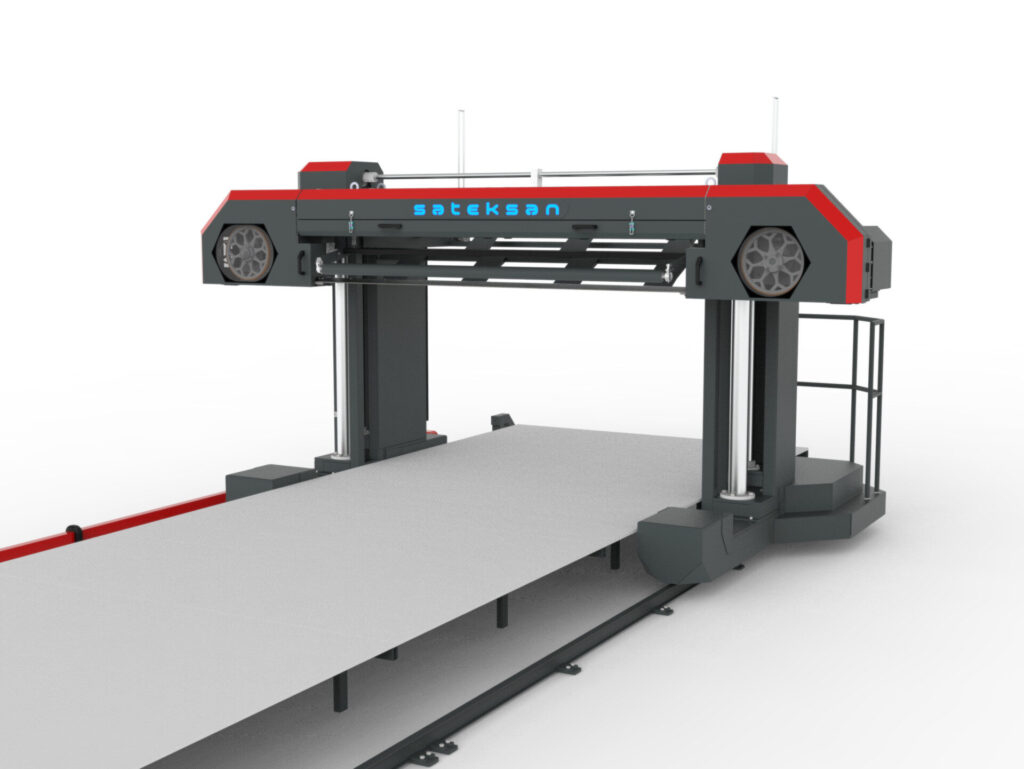

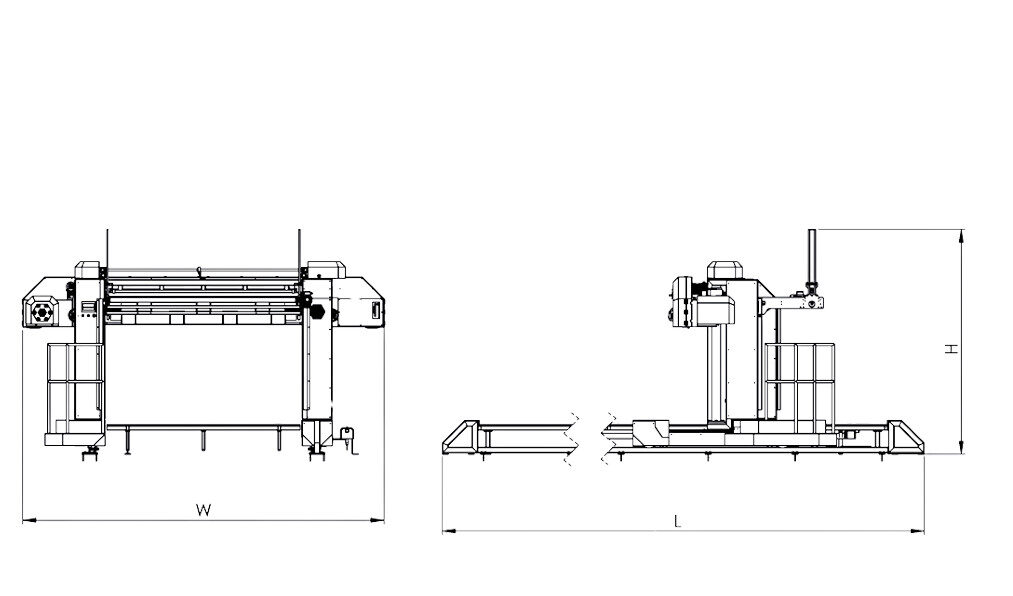

Block Cutter Machine

The BC Series Block Cutter seamlessly integrates with continuous foam casting lines, performing accurate sizing operations synchronized with foam advancement. Its durable strip knife system ensures clean cuts across varying foam densities (15-60kg/m³), while adjustable speeds (0-15 m/min) optimize production flow.

Key Specifications:

- Cutting Area: 2450mm (W) × 1300mm (H)

- Max Length: 60m (adjustable 7-60m)

- Power: 3.7 kW

- Footprint: 6800×3750×3320mm | 2500kg

Ideal for PU, PE, and specialty foam manufacturers requiring high-volume precision cutting.

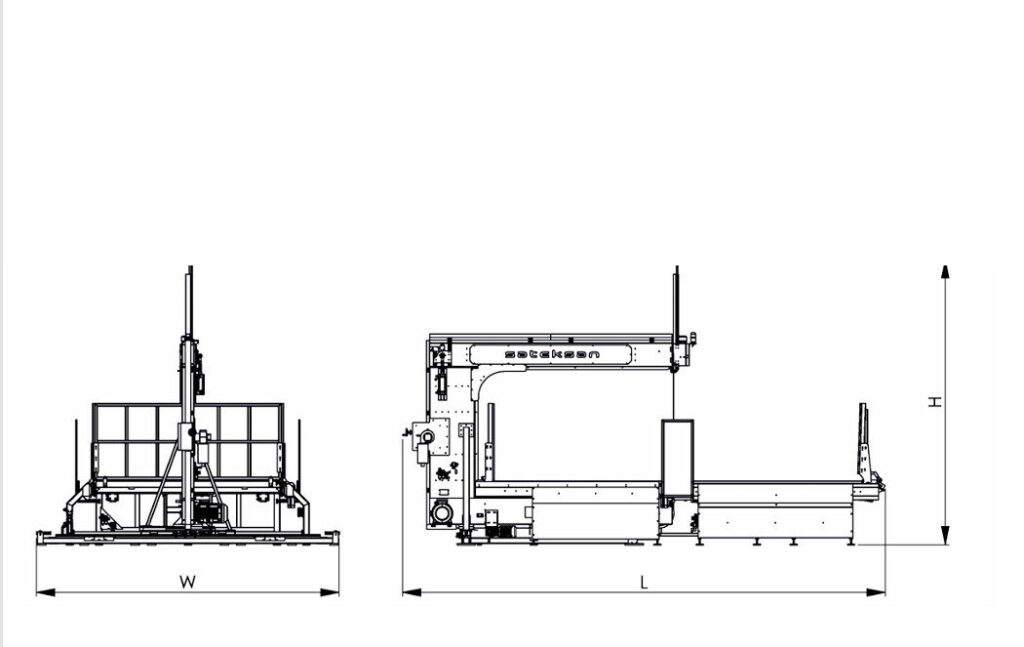

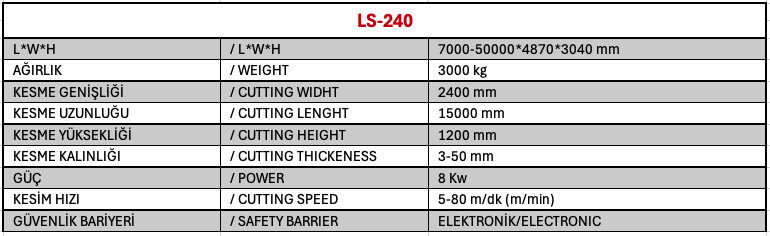

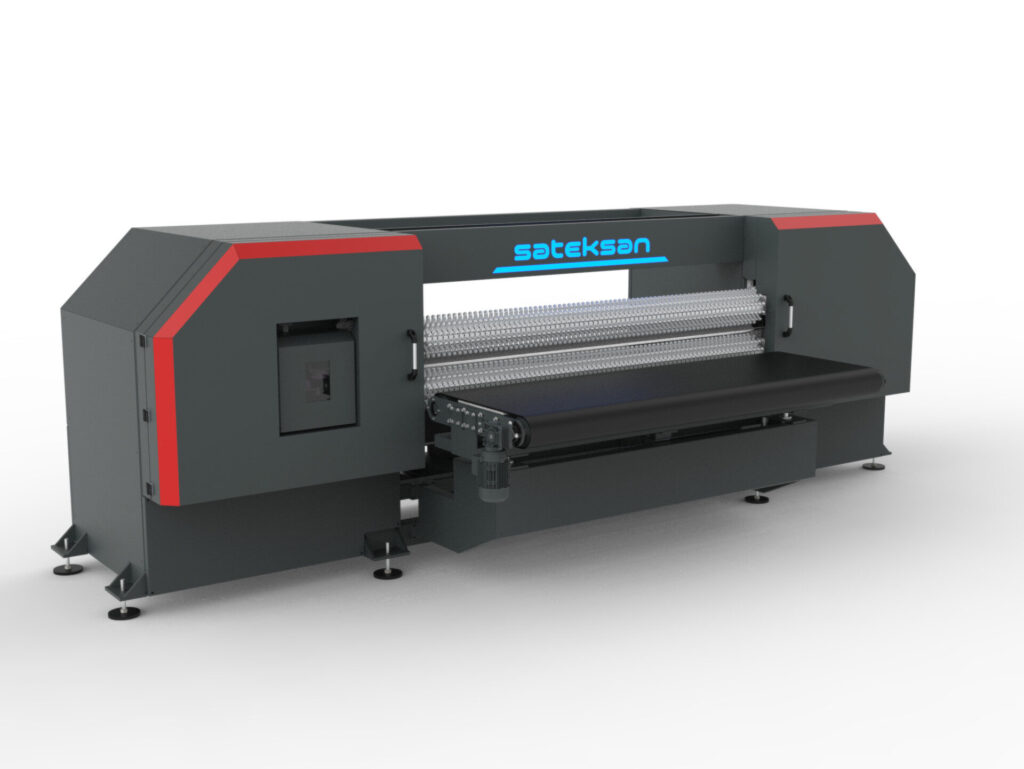

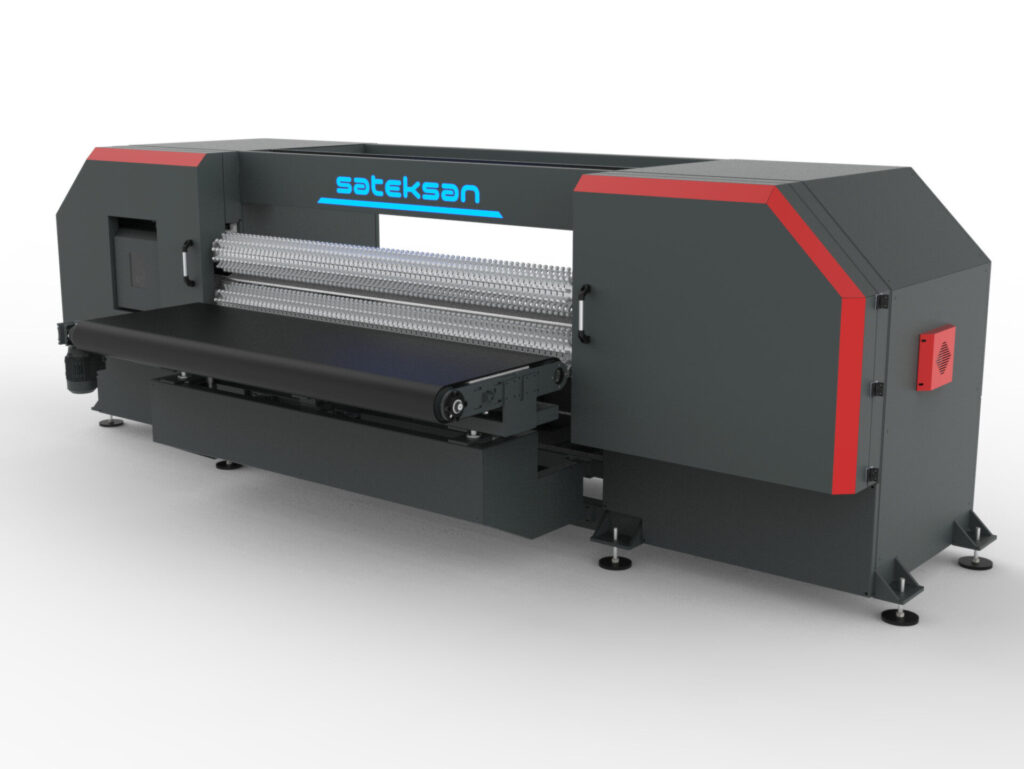

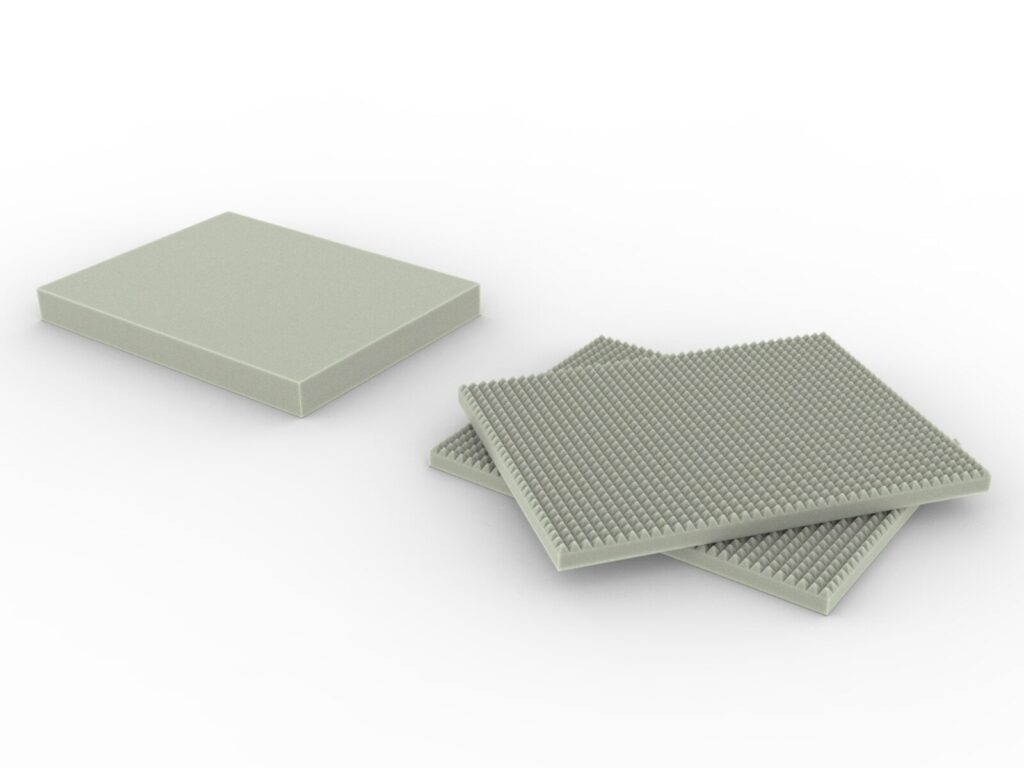

Long Sheet Machine

The LS-240 Long Sheet Machine is engineered for precision slicing of extra-long foam blocks into uniform sheets, with integrated rolling capabilities. Available in two configurations to suit different production needs:

- Rail Model: Features a mobile cutting unit that traverses the length of stationary foam blocks

- Conveyor Model: Incorporates input/output conveyor systems

Key Specifications:

Technical Features:

- Dual Operation Modes:

- Rail-mounted cutting system for stationary blocks

- Conveyor-fed system for continuous production

- Precision Cutting System:

- Adjustable thickness control (3-50 mm)

- High-speed cutting up to 80 m/min

- Safety & Control:

- Integrated safety barriers

- Electronic control system

Applications:

- Mattress topper production

- Automotive interior components

- Packaging material manufacturing

- Specialty foam sheet production

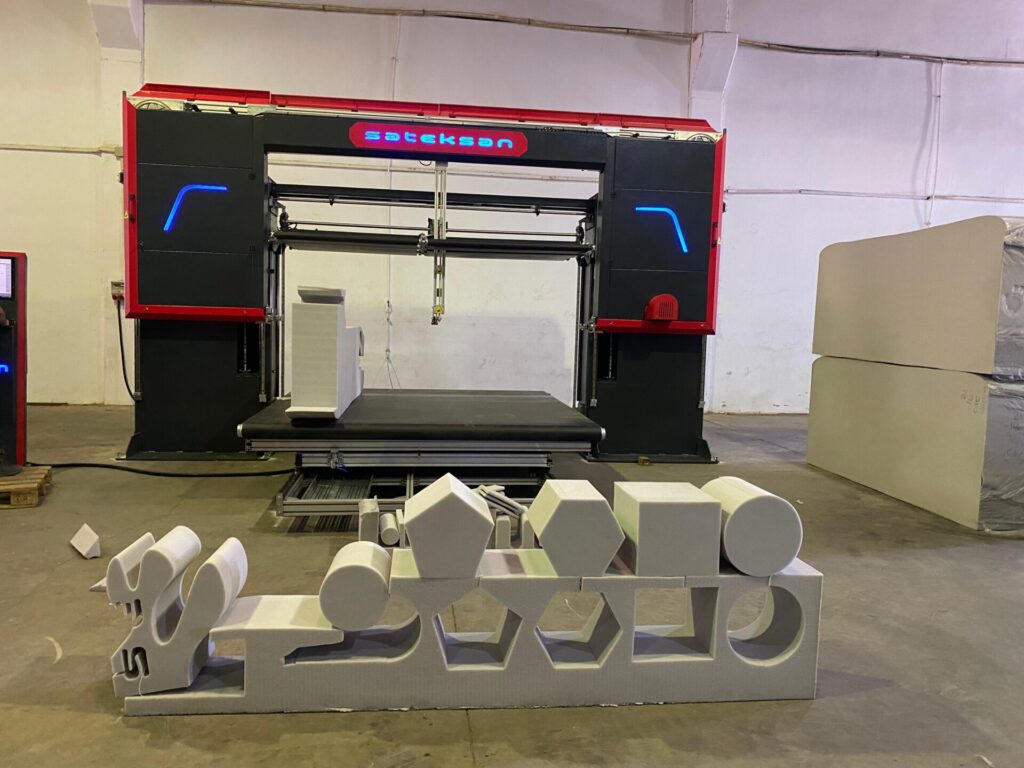

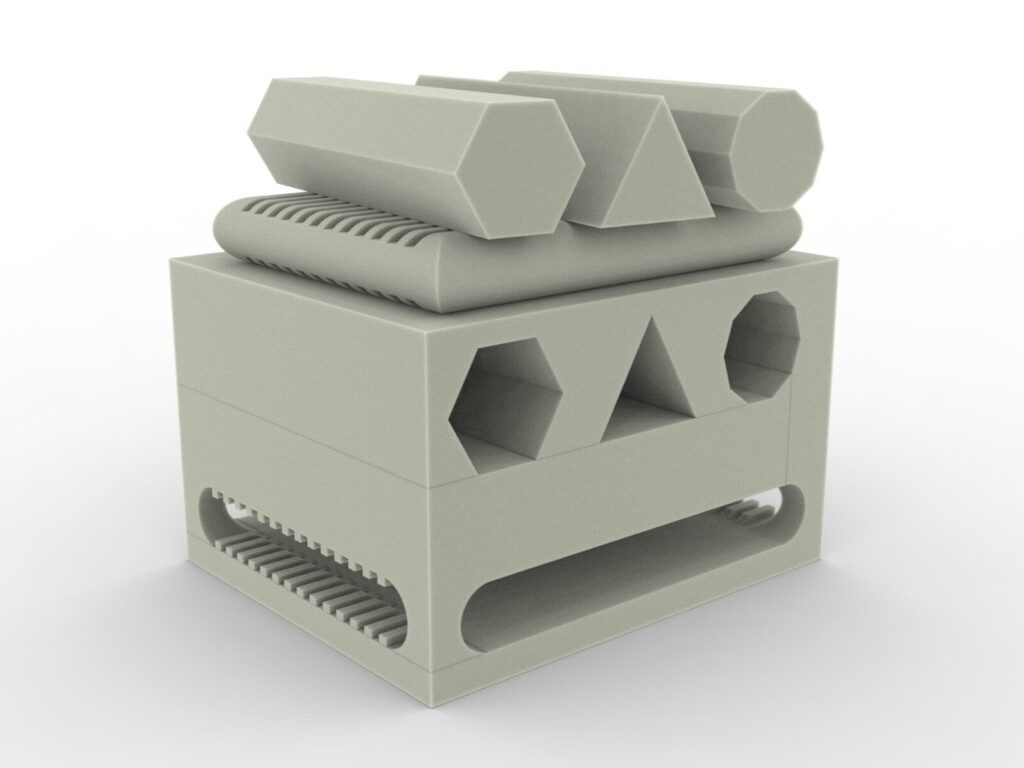

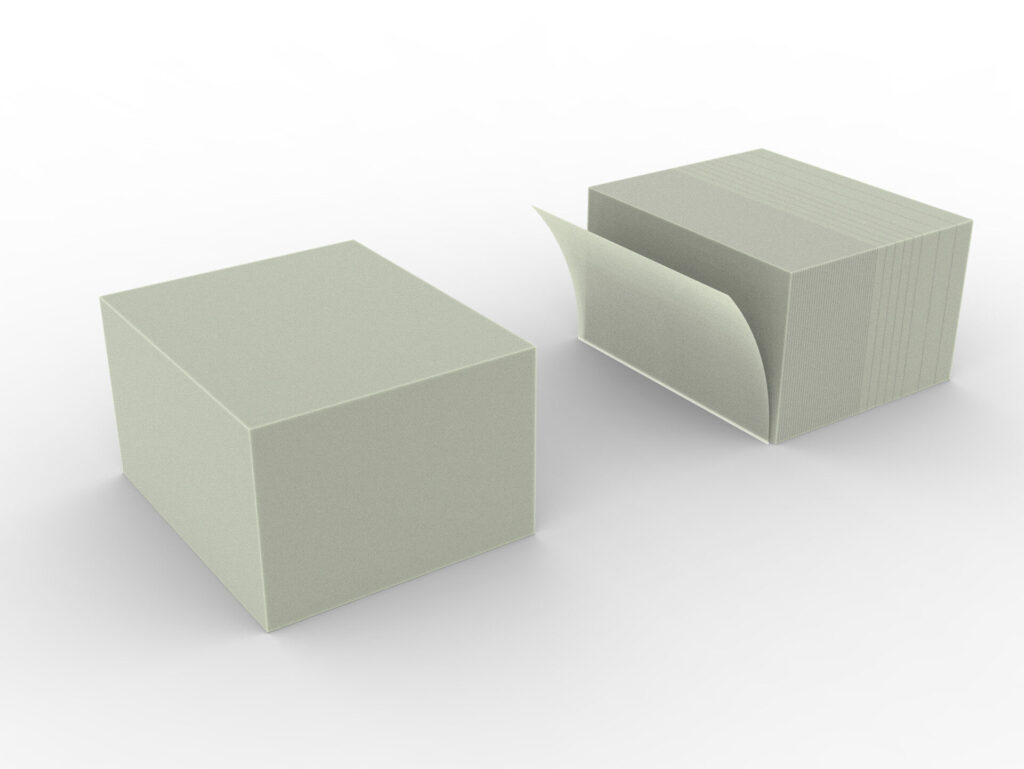

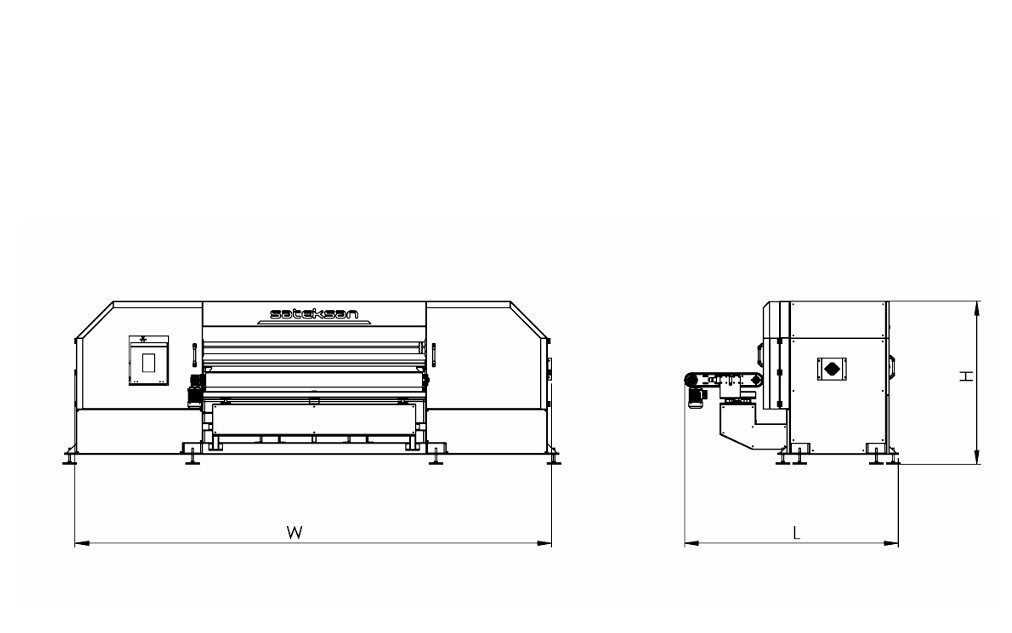

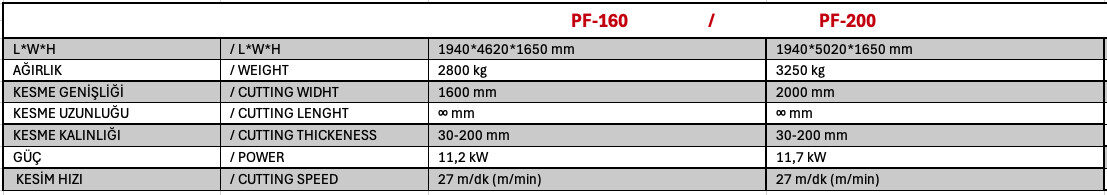

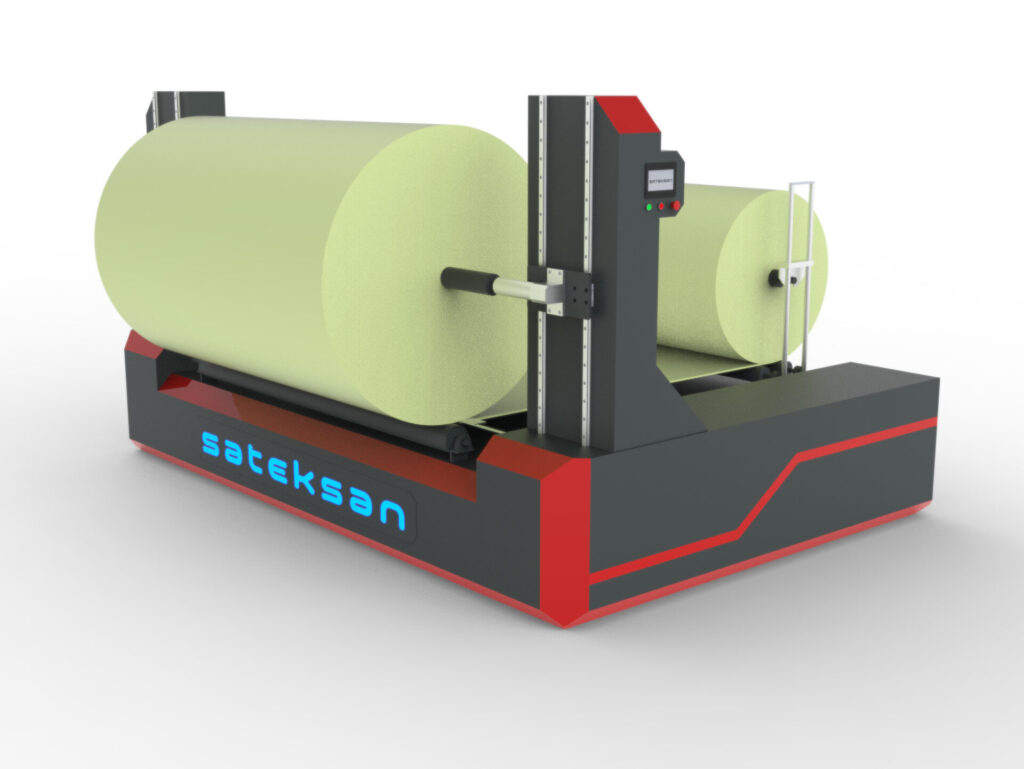

Profiling Machine

The PF-200 is an advanced profiling machine designed for high-speed, die-based shaping of foam blocks into waves, ergonomic patterns, or custom profiles. Its internal cutting technology transforms blocks without altering external dimensions, ideal for mattress toppers, automotive seating, and specialty foam products.

Key Features

✔ Die-Based Precision:

- Mechanical dies create complex internal profiles (waves, grooves, contours)

- Quick-change die system (<5 min swap) for multi-pattern production

✔ Dual Operation Modes:

- Conveyor Model: 27 m/min cutting speed with input/output conveyor belts

- Rail Model: For stationary block processing

✔ Smart Automation:

- Lenze drives + touchscreen panel for speed/die control

- Thickness adjustment: 3–50 mm (programmable)

✔ Industrial Durability:

- 11.2 kW motor for heavy-duty operation

- High-grade steel construction

Applications

- Mattress Toppers: Wave/ergonomic designs

- Automotive: Contoured seat cushions, headrests

- Medical: Orthopedic supports

- Packaging: Custom protective inserts

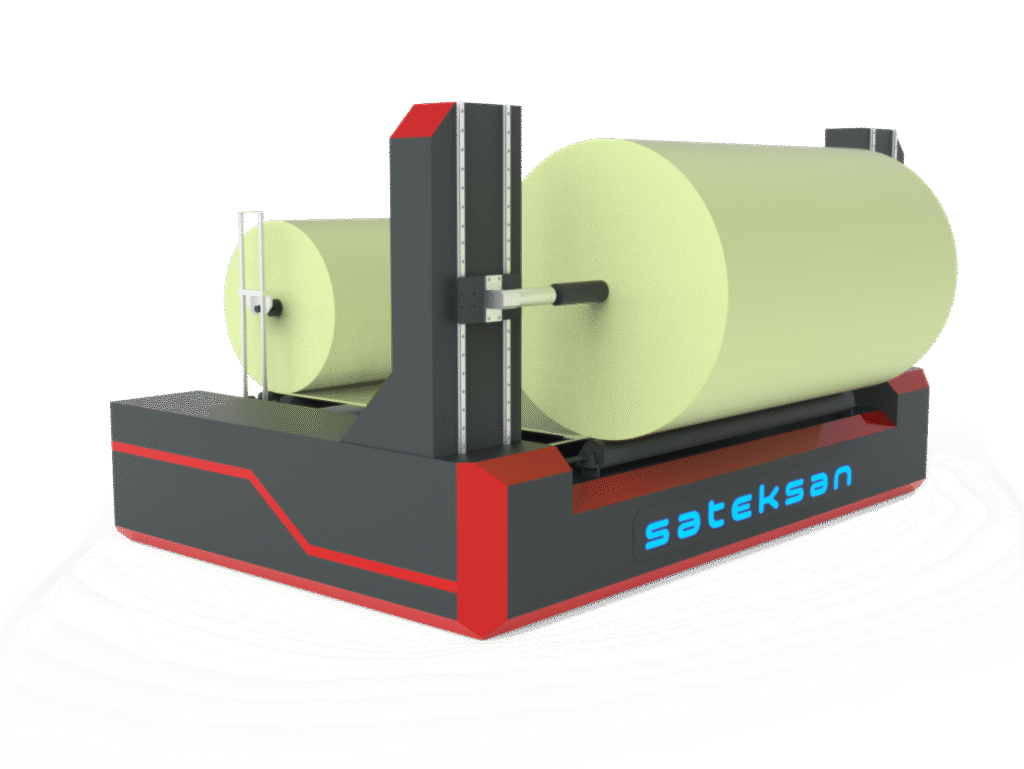

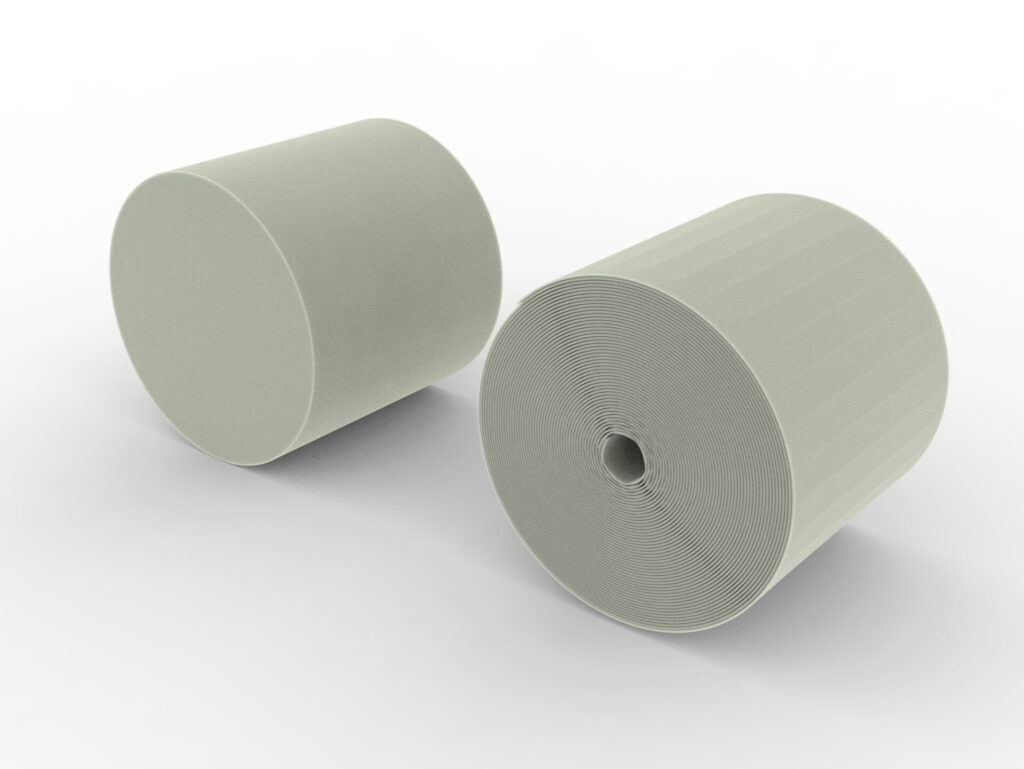

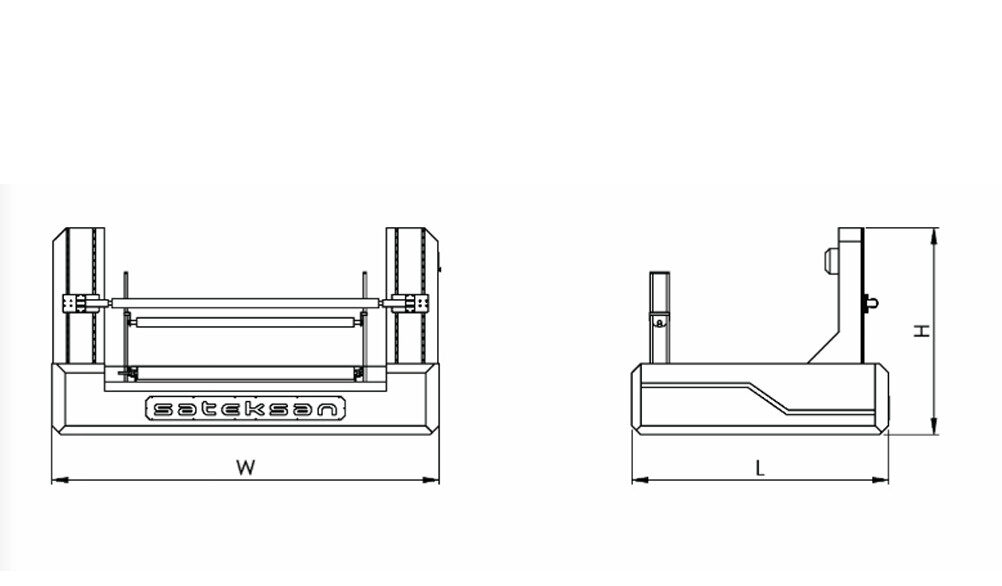

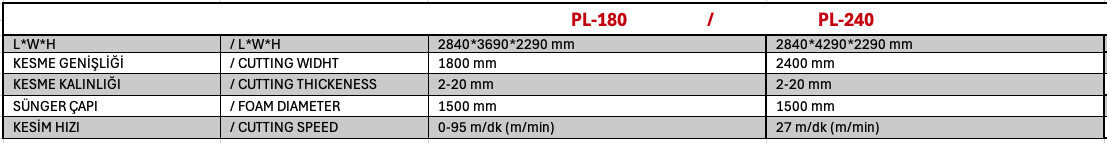

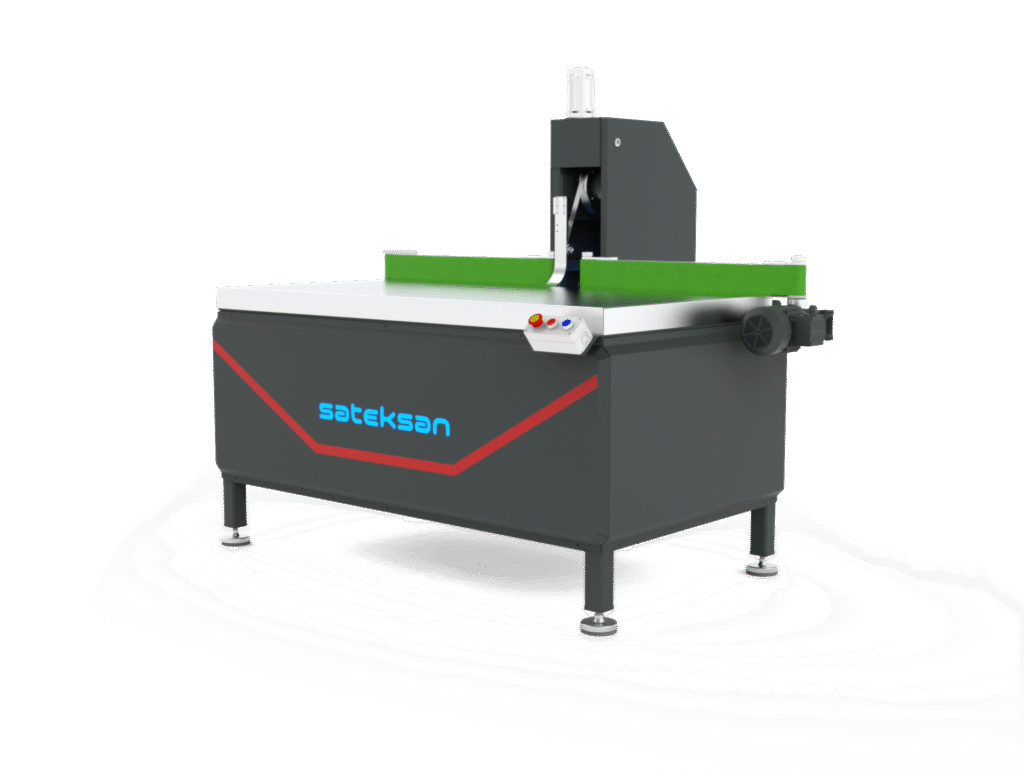

Peeling Machine

The PL-Series peeling machines automate the conversion of foam blocks into uniform sheets through continuous rotary peeling. Designed for 24/7 industrial operation, they maintain constant blade contact while producing rolls of 2-20mm thin foam with <1% material waste.

Key Advantages

✔ Continuous Production: Unlimited length capability with auto-rolling

✔ Precision Thickness Control: 2-20 mm adjustable (±0.2mm tolerance)

✔ Industrial Automation:

- Lenze drives with 7″ touchscreen

- Auto-speed synchronization with foam density

✔ Safety & Durability: - Reinforced steel frame

- Emergency stops + blade guards

Technical Highlights

- Blade System: Tungsten-carbide tipped for 800+ hours of peeling

- Waste Reduction: <1% material loss vs. traditional slicing

- Power: 11 kW (PL-240) / 9 kW (PL-180)

Applications

- Mattress Liners: Ultra-thin foam layers

- Automotive: Peeled sheets for headliners

- Medical: Precision foam for prosthetics

- Packaging: Custom protective rolls

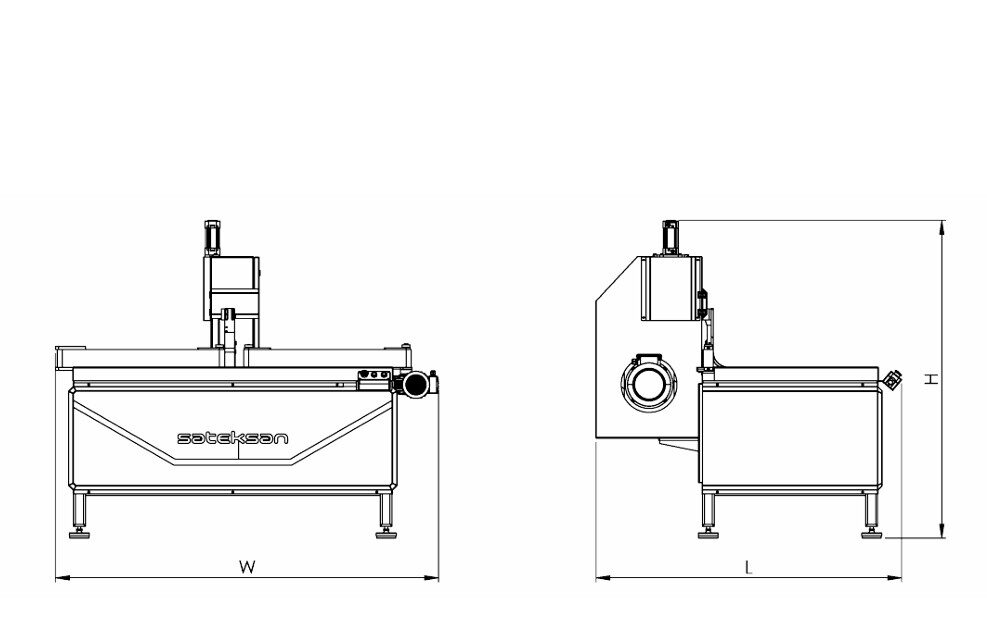

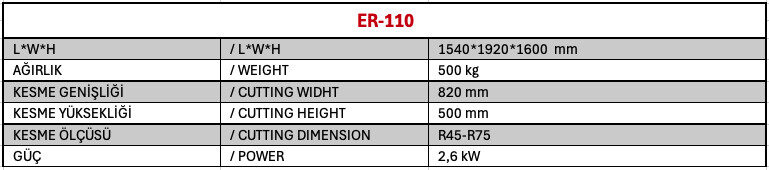

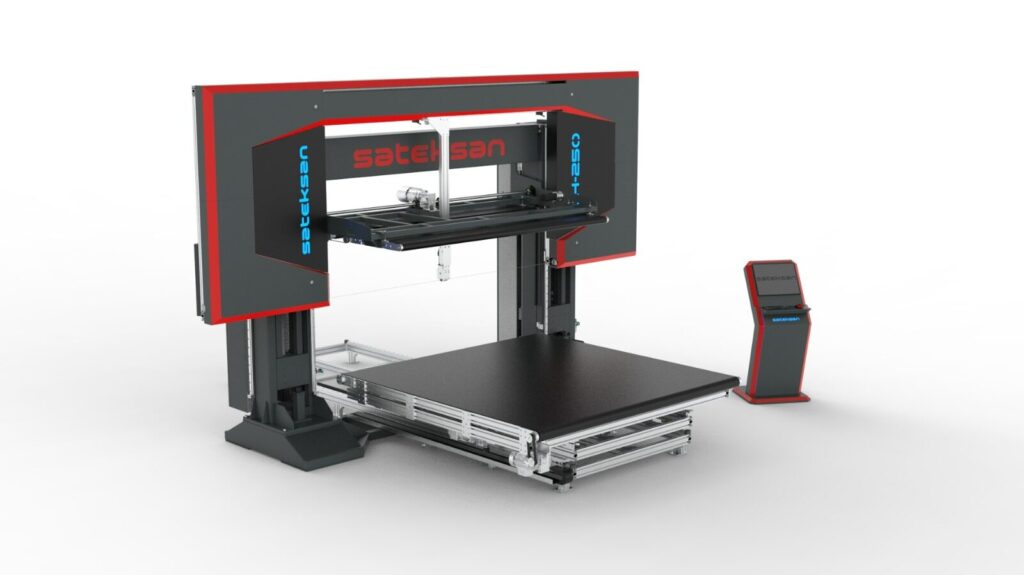

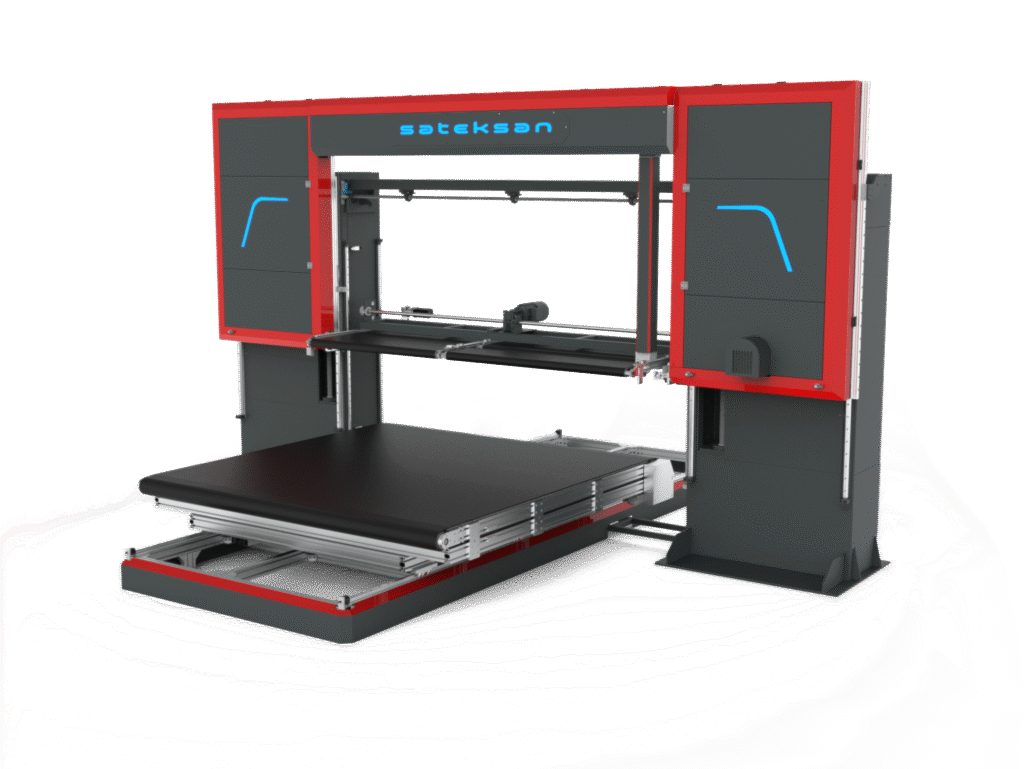

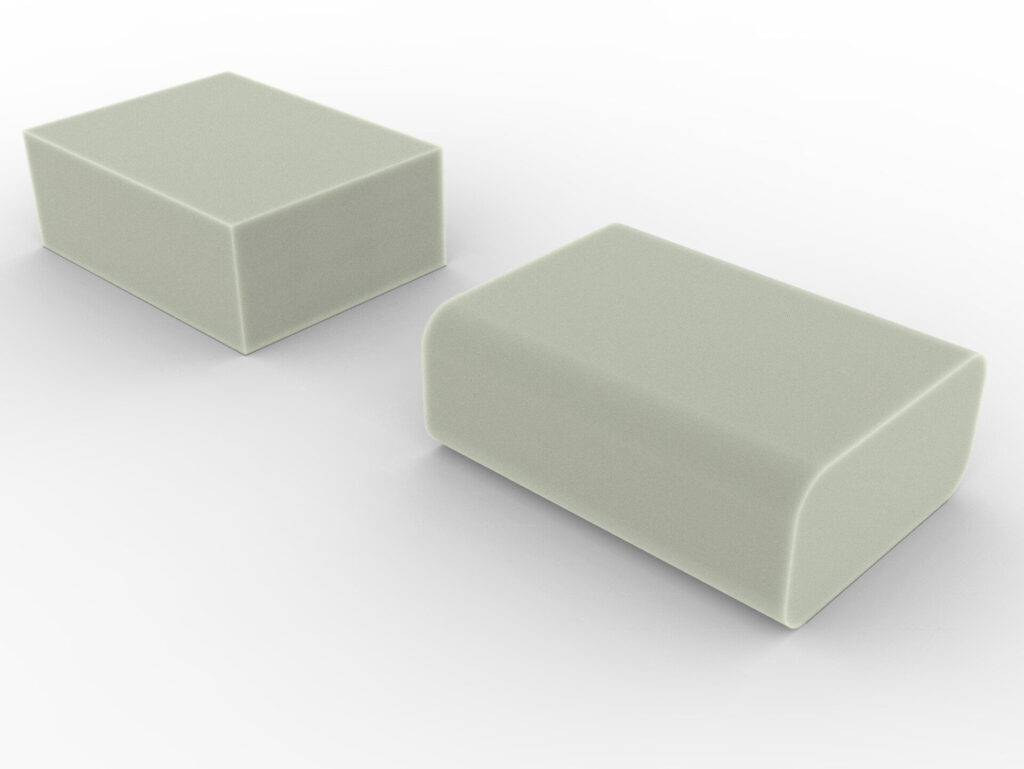

Edge Rounding Machine

The ER-110 transforms sharp-cut foam edges into smooth, furniture-ready profiles with R45-R75 radius options. Designed as a perfect complement to Sateksan slicing machines, it eliminates manual grinding with die-based precision and rapid changeover.

Key Features

✔ Multi-Profile Capacity: 10+ interchangeable dies (standard)

✔ Compact & Efficient: 1.5m footprint processes 820mm wide foam

✔ Industrial-Grade: 2.6kW motor handles PU, memory foam, latex

✔ Safety Focus: Guarded dies + emergency stop

Applications

- Furniture Manufacturing: Sofa arms, seat cushions

- Mattress Production: Pillow top edges

- Automotive Interiors: Door panel foams

- Medical Equipment: Cushion edge finishing