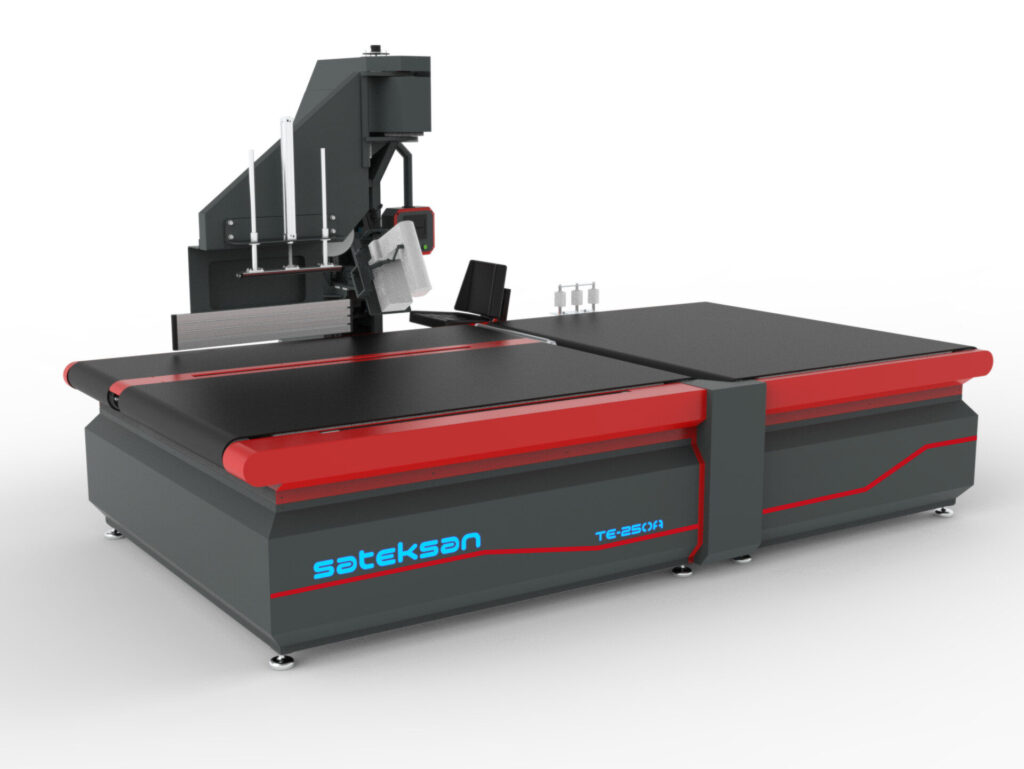

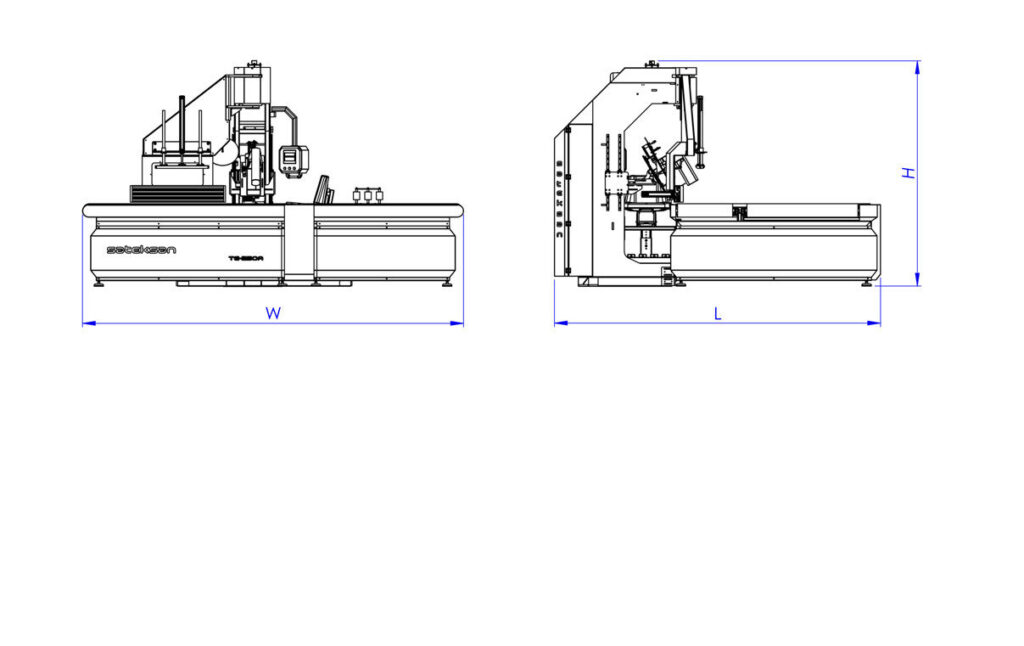

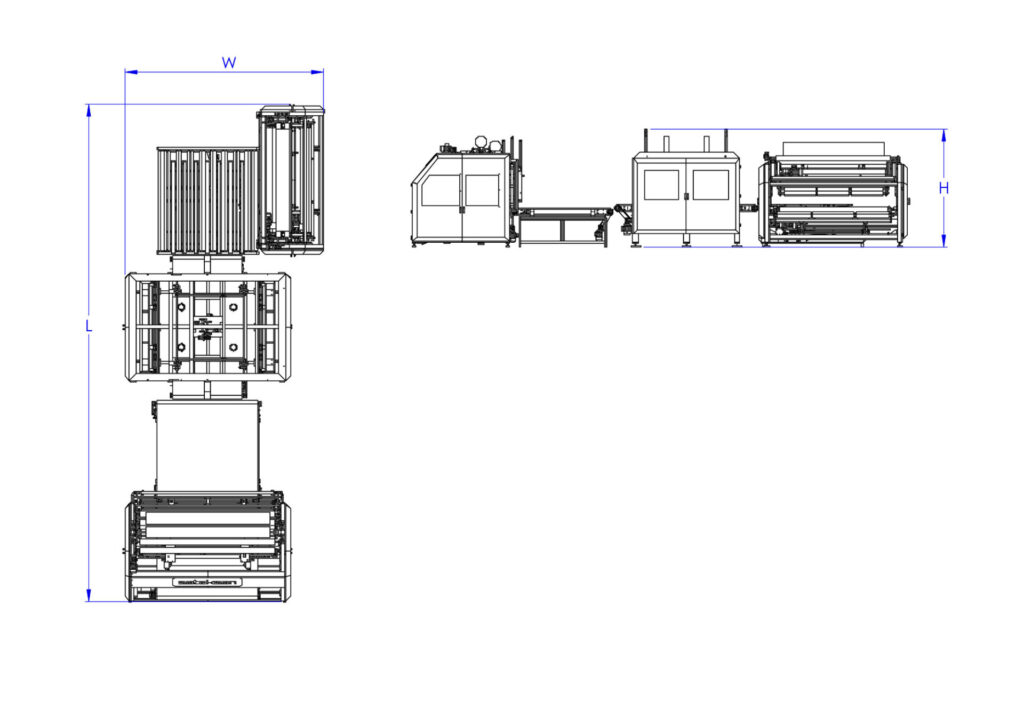

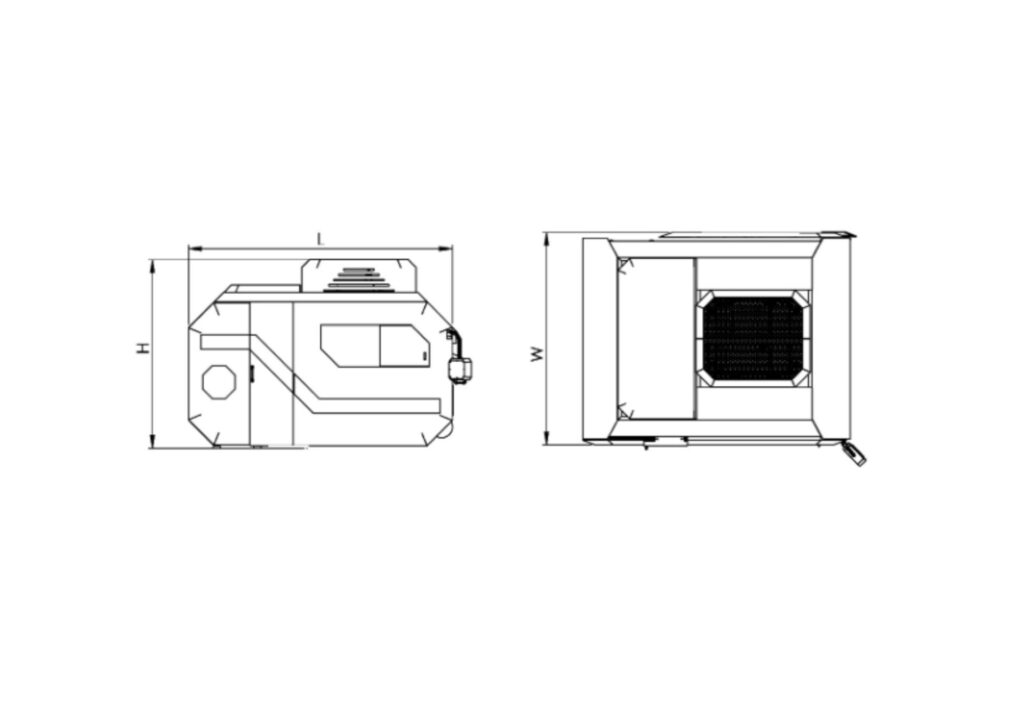

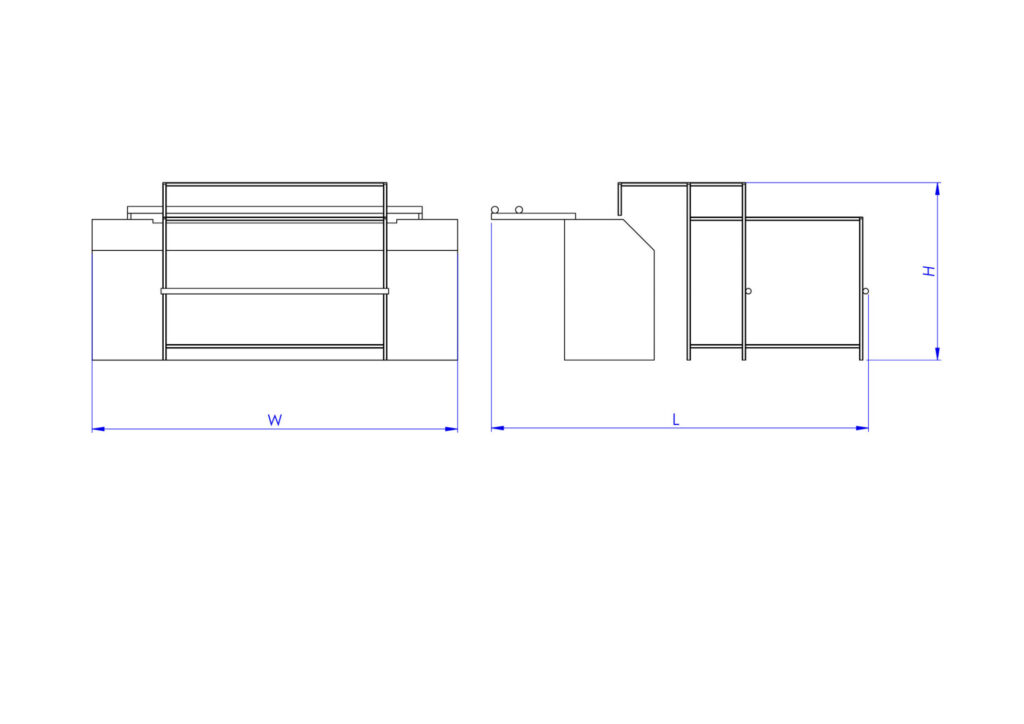

Automatic Tape Edge Machine

With our operator support systems and ergonomic design, we offer a system that is specifically engineered to substantially cut labor costs while optimizing operator productivity. The bed turning system makes usage extremely comfortable. Furthermore, we deliver superior sewing performance through state-of-the-art stitching technology. The servo system employed in the sewing motor elevates quality by enabling precision stitching. In this manner, we enhance the efficiency and continuity of your industrial processes.

With our operator support systems and ergonomic design, we offer a system that is specifically engineered to substantially cut labor costs while optimizing operator productivity. The bed turning system makes usage extremely comfortable. Furthermore, we deliver superior sewing performance through state-of-the-art stitching technology. The servo system employed in the sewing motor elevates quality by enabling precision stitching. In this manner, we enhance the efficiency and continuity of your industrial processes.

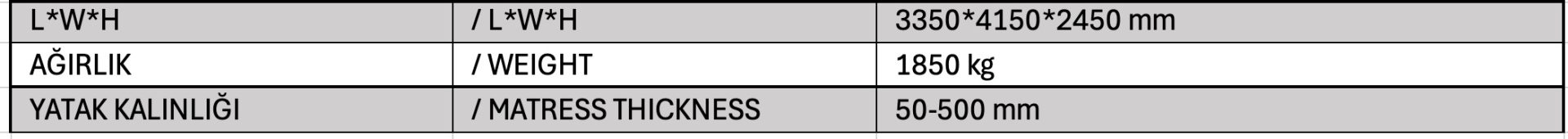

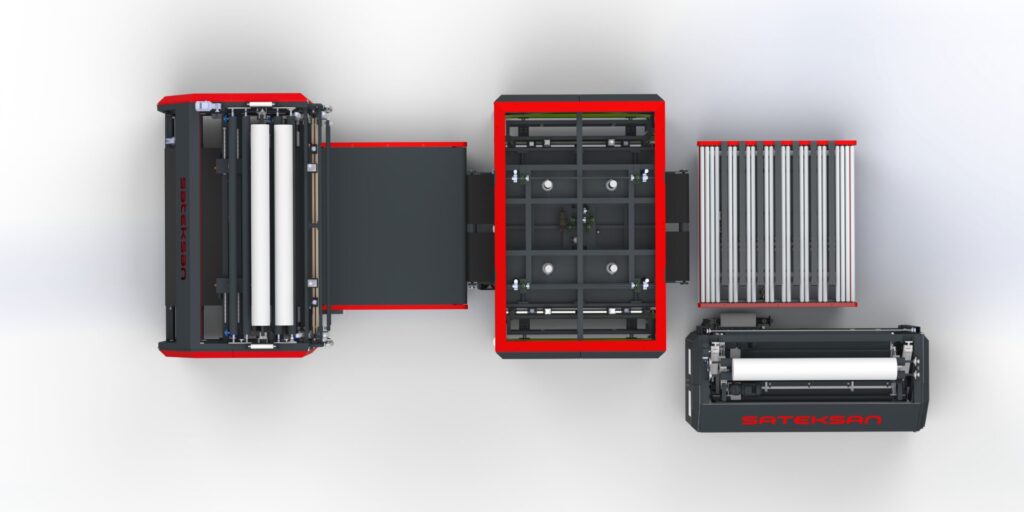

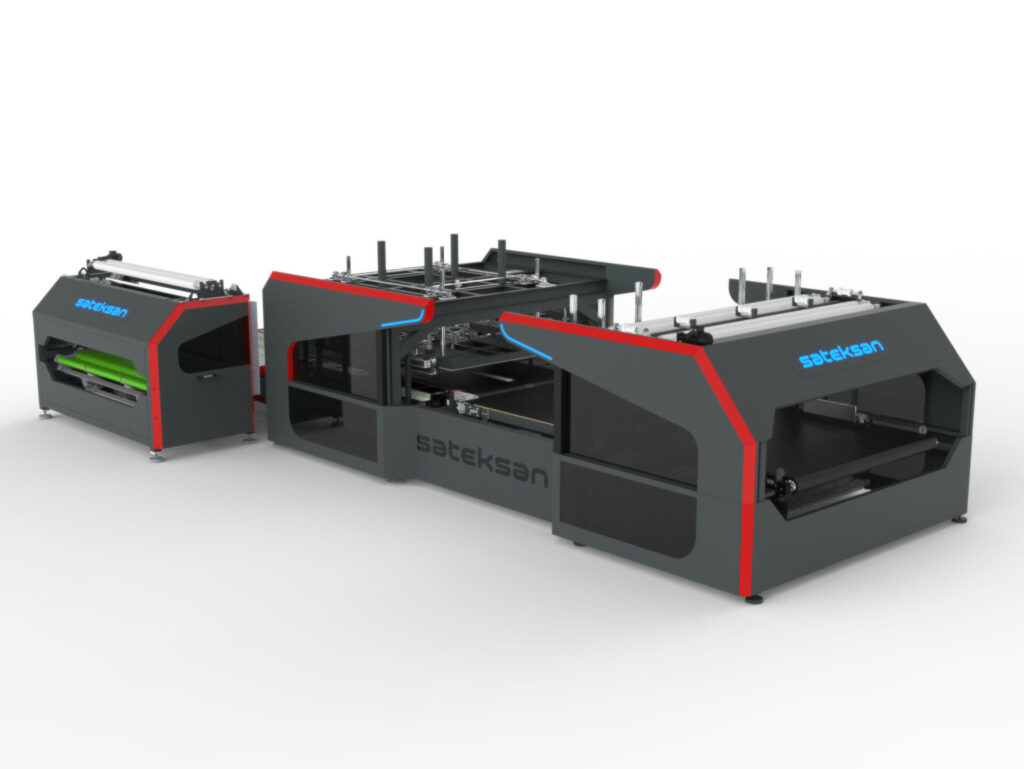

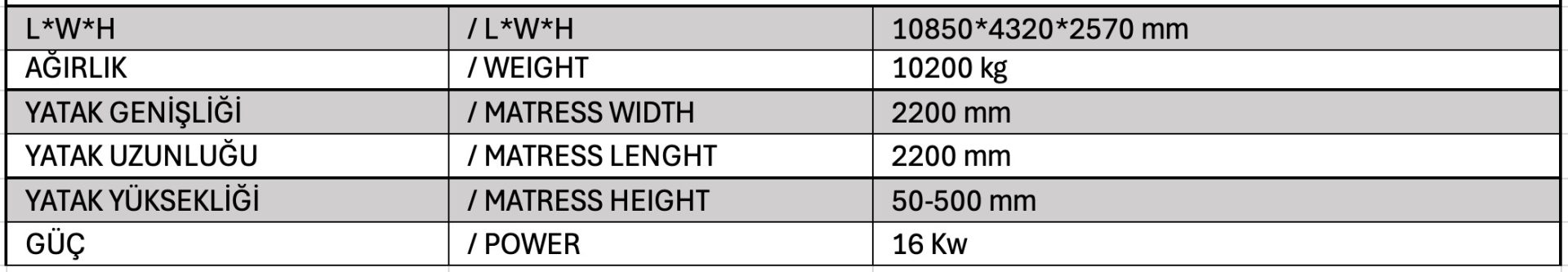

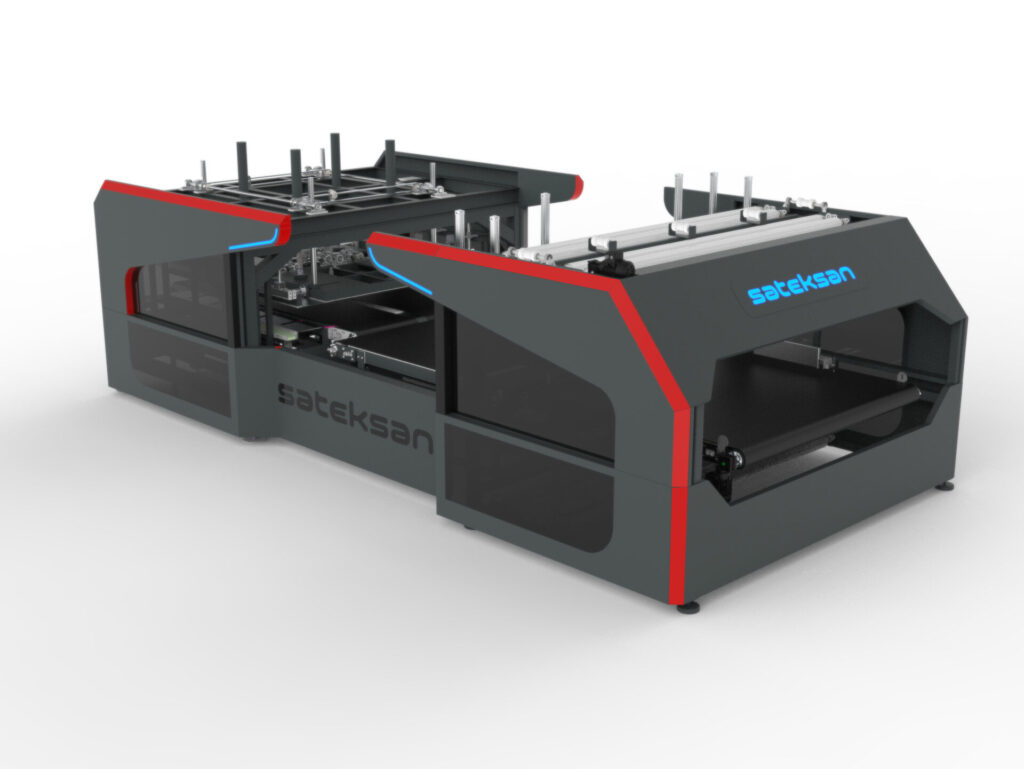

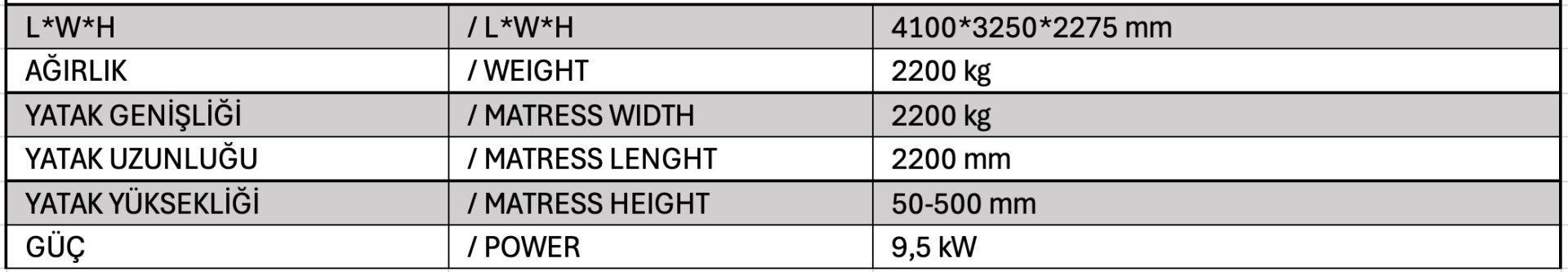

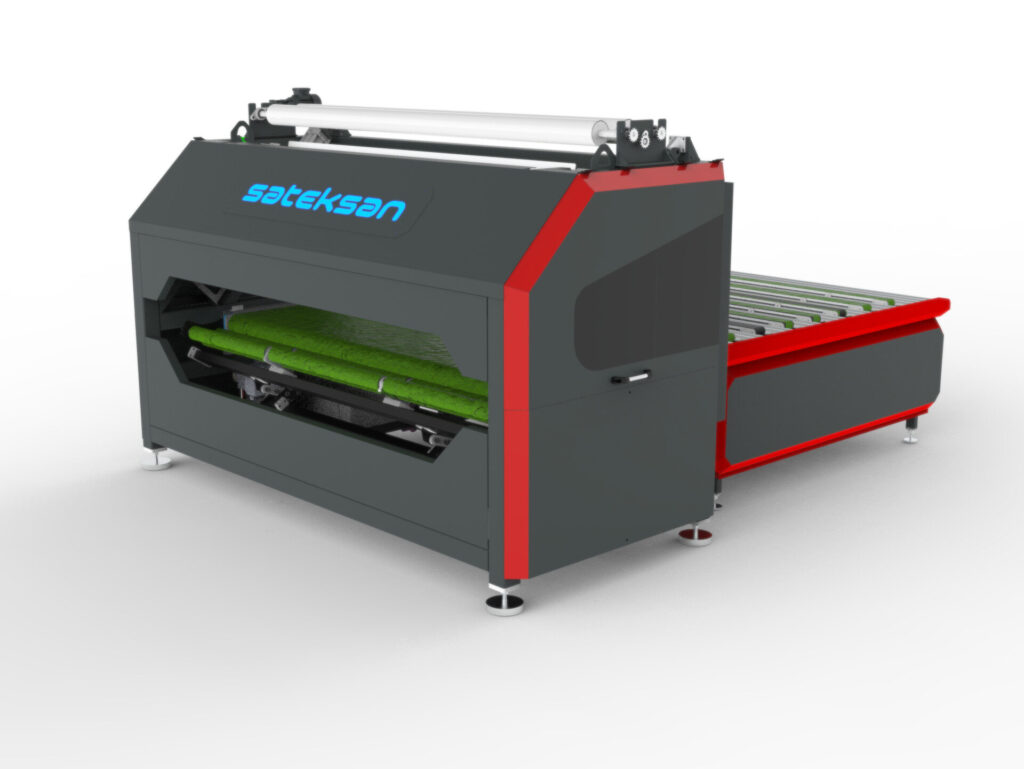

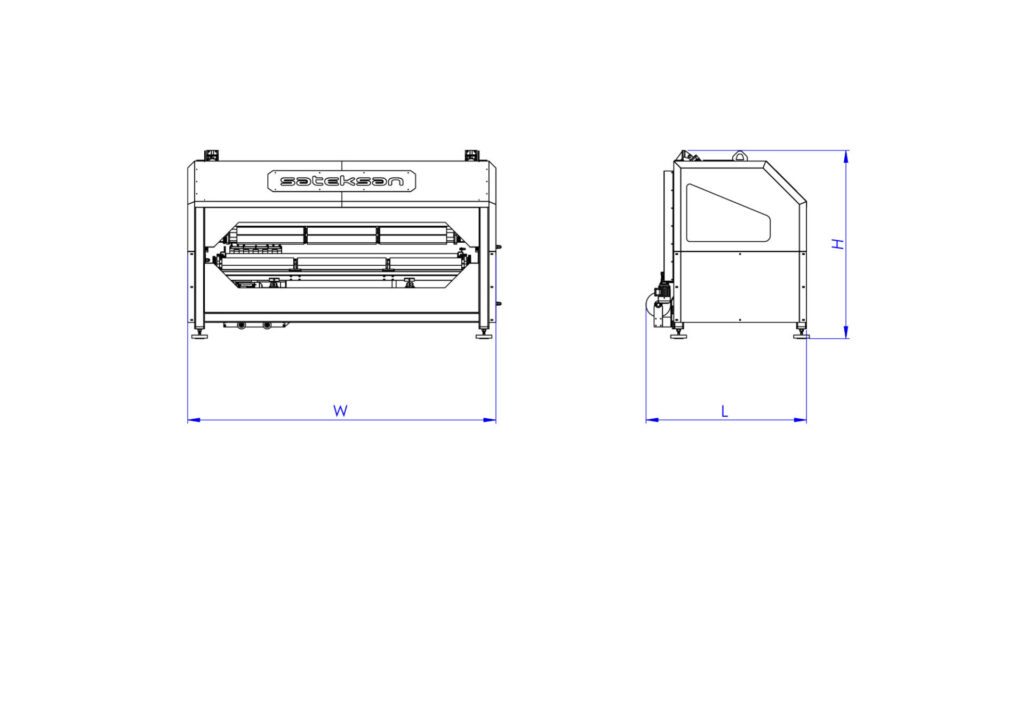

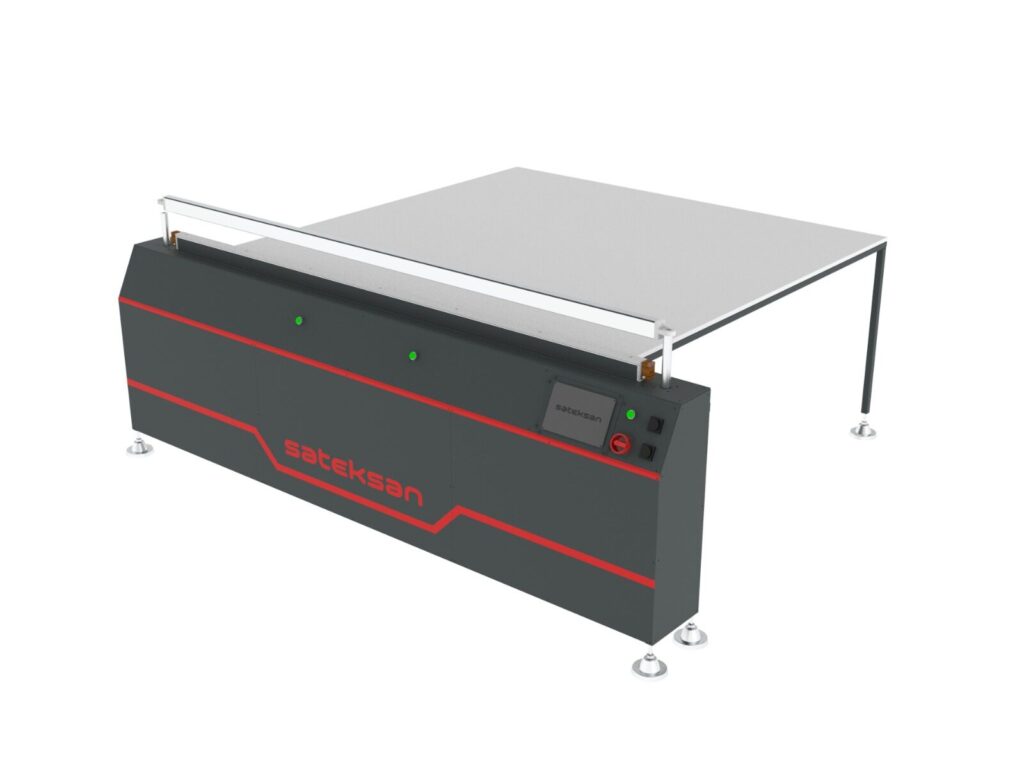

Fullpack Machine

FULLPACK is designed as a fully automated mattress packaging machine, offering unparalleled flexibility. This versatile system effortlessly packages mattresses, mattress pads, bases, and headboards of varying sizes without the need for manual adjustments. With a packaging capacity of up to 2 mattresses per minute, FULLPACK guarantees error-free production thanks to its automated measurement system, which precisely gauges mattress width, length, and height. Furthermore, it offers an automatic edge nylon bonding system, automatic edge nylon cutting system, and automatic disposal of cut edge nylon, resulting in clean and accurate mattress packaging. The inclusion of an edge bonding system further reinforces the security of mattress packaging, and it allows for customization in adjusting heating and cooling times for different nylon thicknesses. Plus, FULLPACK offers online service and training options to support customers, ensuring the seamless operation of the system and an overall boost in efficiency.

FULLPACK is designed as a fully automated mattress packaging machine, offering unparalleled flexibility. This versatile system effortlessly packages mattresses, mattress pads, bases, and headboards of varying sizes without the need for manual adjustments. With a packaging capacity of up to 2 mattresses per minute, FULLPACK guarantees error-free production thanks to its automated measurement system, which precisely gauges mattress width, length, and height. Furthermore, it offers an automatic edge nylon bonding system, automatic edge nylon cutting system, and automatic disposal of cut edge nylon, resulting in clean and accurate mattress packaging. The inclusion of an edge bonding system further reinforces the security of mattress packaging, and it allows for customization in adjusting heating and cooling times for different nylon thicknesses. Plus, FULLPACK offers online service and training options to support customers, ensuring the seamless operation of the system and an overall boost in efficiency.

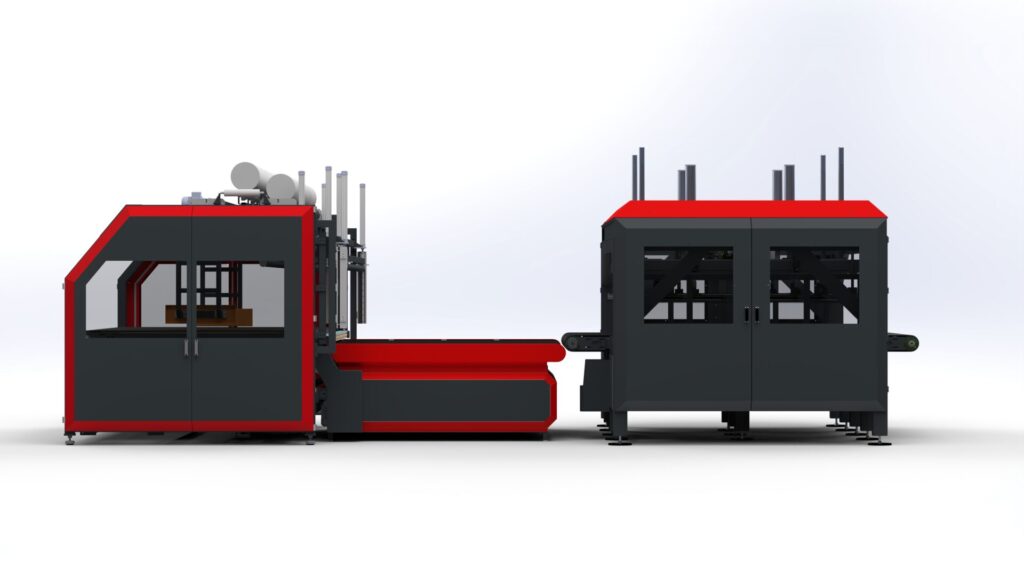

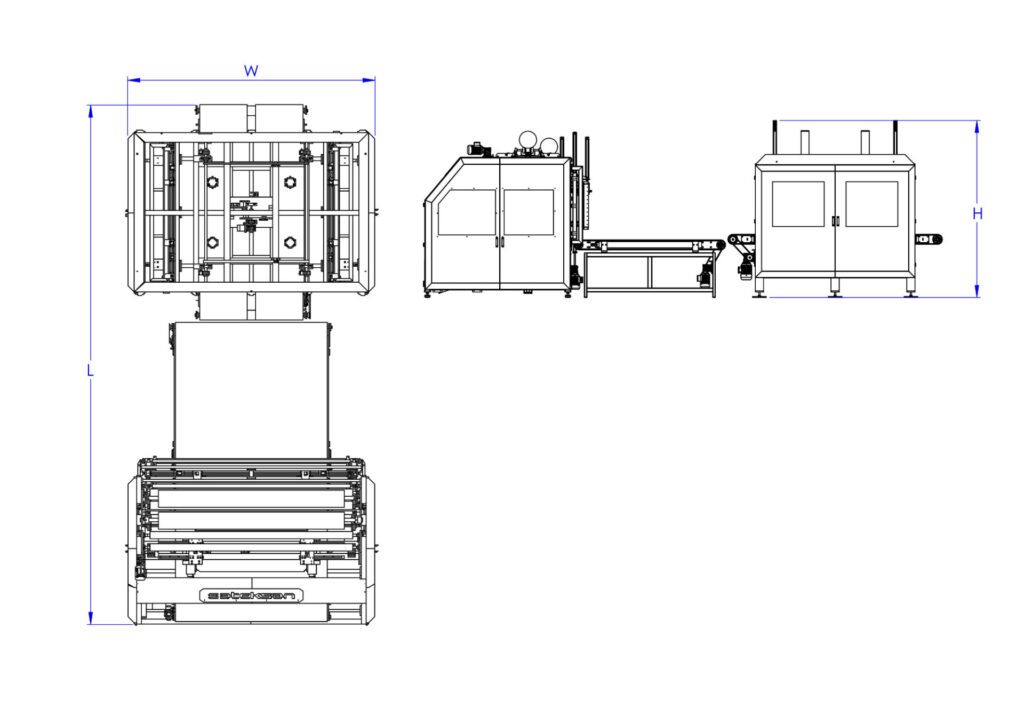

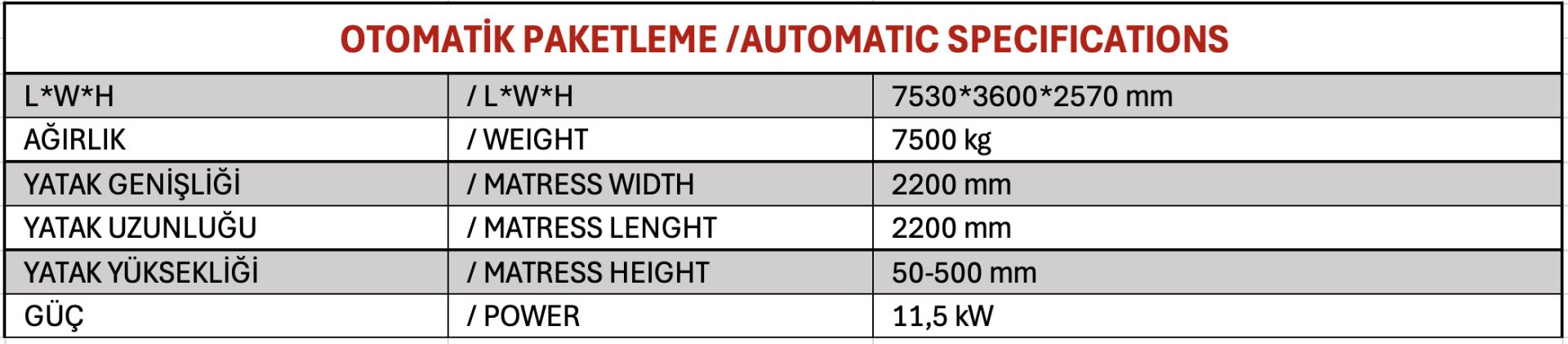

Automatic Packing

Automatic mattress packaging machine is designed for packaging mattresses without the need for an operator. This unique design allows for

packaging in different modes, including standard packaging at the desired height and the thinnest form. Furthermore, it simplifies workflow and

increases efficiency by combining mattress packaging and compression processes on a single machine. This machine not only makes your operations

more effective but also allows you to minimize costs.

Automatic mattress packaging machine is designed for packaging mattresses without the need for an operator. This unique design allows for

packaging in different modes, including standard packaging at the desired height and the thinnest form. Furthermore, it simplifies workflow and

increases efficiency by combining mattress packaging and compression processes on a single machine. This machine not only makes your operations

more effective but also allows you to minimize costs.

Press Rollpack Machine

It is designed to work together with an automatic pressing machine to perform the packaging process, aiming to minimize shipping, storage and operation expenses.

It is designed to work together with an automatic pressing machine to perform the packaging process, aiming to minimize shipping, storage and operation expenses.

Rollpack Machine

This system is engineered for rolling mattresses made of different densities and foam. It possesses the capability to automatically determine the output diameter based on material density and internal resistance. Plus, the machine offers flexibility to make adjustments in the roll diameter within a range of (-10 / +10)%. This feature ensures achieving the desired output diameter. The machine stretches the stretch film wrapping process by 2.5 to 3 times. This approach not only helps reduce packaging costs but also provides a higher quality wrapping result. It enhances business efficiency by ensuring these products are packaged and transported securely and smoothly.

This system is engineered for rolling mattresses made of different densities and foam. It possesses the capability to automatically determine the output diameter based on material density and internal resistance. Plus, the machine offers flexibility to make adjustments in the roll diameter within a range of (-10 / +10)%. This feature ensures achieving the desired output diameter. The machine stretches the stretch film wrapping process by 2.5 to 3 times. This approach not only helps reduce packaging costs but also provides a higher quality wrapping result. It enhances business efficiency by ensuring these products are packaged and transported securely and smoothly.

Manuel Packing Machine

This system is equipped with a double-piston jaw compression mechanism, delivering substantial compression force during mattress packaging. It ensures secure packaging by incorporating a resistance tensioning system, guaranteeing the safe transport of products. Moreover, this packaging system is also capable of packaging mattresses with corner cardboard, which expands your product options. It offers flexibility by enabling you to fine-tune heating and cooling times for different materials. The double-stitch bonding feature enhances package durability, ensuring strong protection of products. For added efficiency and streamlined packaging processes, an additional table option is available. This system provides a dependable and versatile solution for your mattress packaging operations, catering to your diverse needs

This system is equipped with a double-piston jaw compression mechanism, delivering substantial compression force during mattress packaging. It ensures secure packaging by incorporating a resistance tensioning system, guaranteeing the safe transport of products. Moreover, this packaging system is also capable of packaging mattresses with corner cardboard, which expands your product options. It offers flexibility by enabling you to fine-tune heating and cooling times for different materials. The double-stitch bonding feature enhances package durability, ensuring strong protection of products. For added efficiency and streamlined packaging processes, an additional table option is available. This system provides a dependable and versatile solution for your mattress packaging operations, catering to your diverse needs

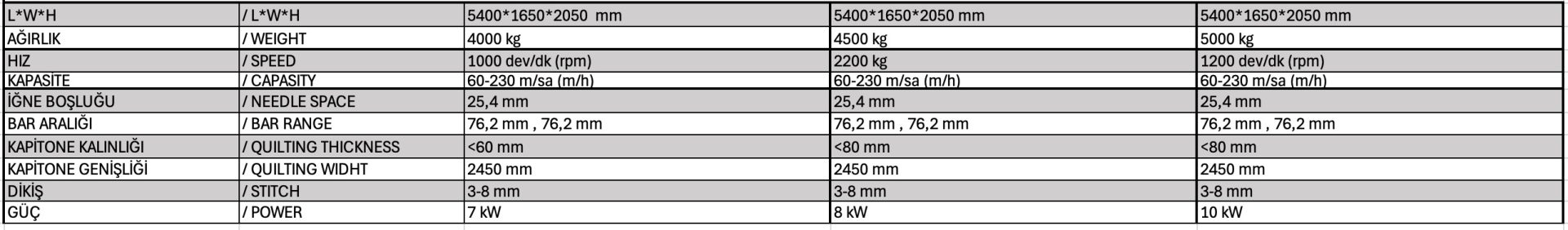

Quilting Machine

Quilting machine ensures comfortable and safe sewing, thanks to its automatic stop feature. It excels in creating patterns on a wide range of materials, from delicate garment fabrics to thick bedding materials. Furthermore, with the CAD pattern system, you can easily create your own unique patterns as well as existing patterns. This allows you to personalize your sewing projects and be creative.

Quilting machine ensures comfortable and safe sewing, thanks to its automatic stop feature. It excels in creating patterns on a wide range of materials, from delicate garment fabrics to thick bedding materials. Furthermore, with the CAD pattern system, you can easily create your own unique patterns as well as existing patterns. This allows you to personalize your sewing projects and be creative.

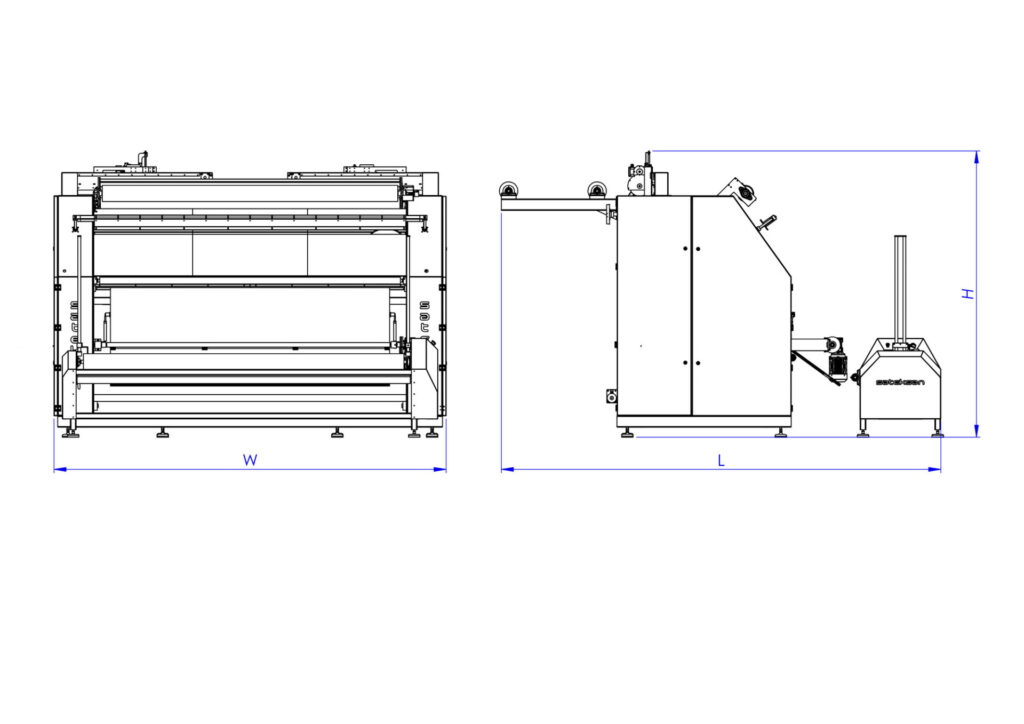

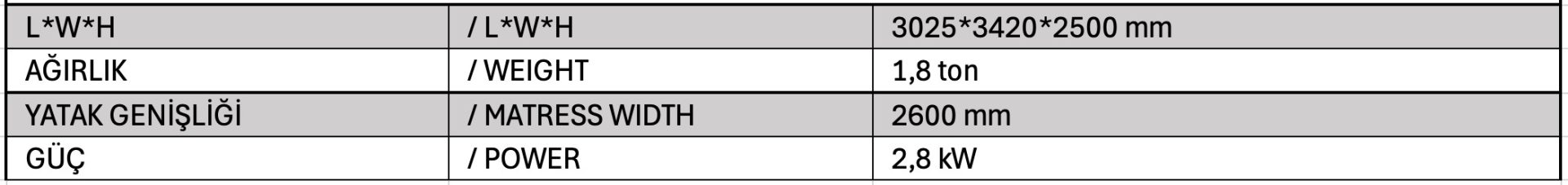

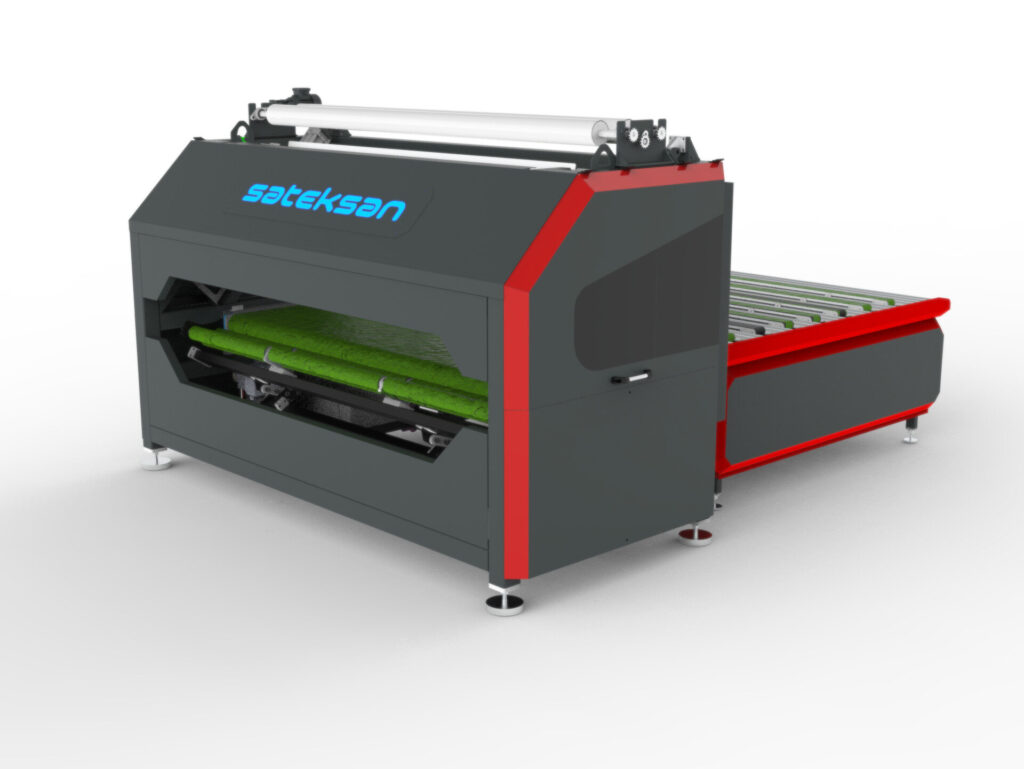

Quilting Back Fabric Cutting Machine

It offers perfect compatibility with other quilting machines with its high-speed operation feature. This quilting cutting machine, which is an excellent choice to enhance your quality, has the ability to make precise cuts with its 10 knifes. It stands out with its ability to make error-free cuts in the desired dimensions. It provides high performance in your cutting operations

It offers perfect compatibility with other quilting machines with its high-speed operation feature. This quilting cutting machine, which is an excellent choice to enhance your quality, has the ability to make precise cuts with its 10 knifes. It stands out with its ability to make error-free cuts in the desired dimensions. It provides high performance in your cutting operations

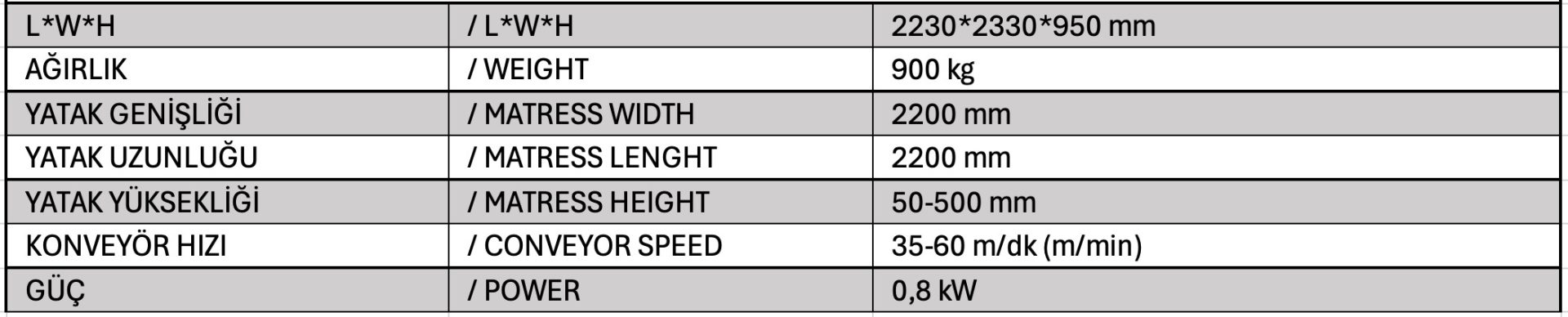

Quality Control Machine

We provide an automated bed lifting, rotating, and turning station specifically designed to alleviate fatigue and enhance work efficiency at inspection or assembly stations. This station effortlessly and smoothly rotates and lifts beds weighing up to 150 kg, guaranteeing operators can maintain peak efficiency throughout the workday. Our system boasts an automatic bed centering feature and can be seamlessly integrated into any production line. Post-rotation, our four-arm turning mechanism gently lowers mattresses to prevent damage. A robust conveyor system and pallet utilization, this system excels in carrying heavy loads with unwavering reliability. Furthermore, our system offers the flexibility to accommodate both single and double operators, enabling you to optimize your workflow and elevate overall operational efficiency.

We provide an automated bed lifting, rotating, and turning station specifically designed to alleviate fatigue and enhance work efficiency at inspection or assembly stations. This station effortlessly and smoothly rotates and lifts beds weighing up to 150 kg, guaranteeing operators can maintain peak efficiency throughout the workday. Our system boasts an automatic bed centering feature and can be seamlessly integrated into any production line. Post-rotation, our four-arm turning mechanism gently lowers mattresses to prevent damage. A robust conveyor system and pallet utilization, this system excels in carrying heavy loads with unwavering reliability. Furthermore, our system offers the flexibility to accommodate both single and double operators, enabling you to optimize your workflow and elevate overall operational efficiency.

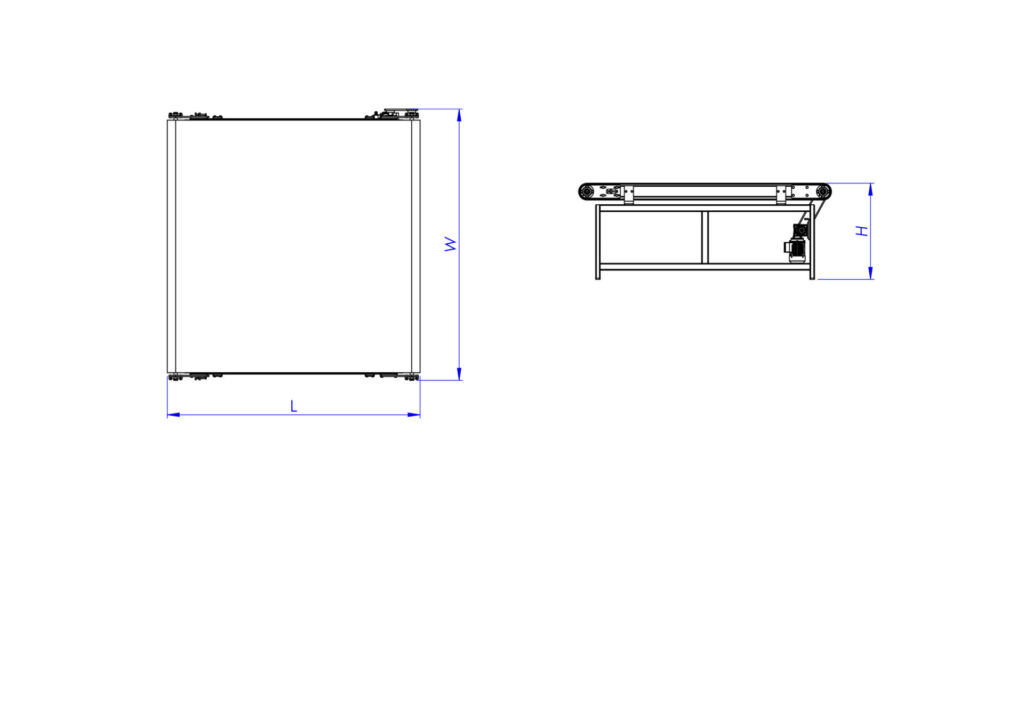

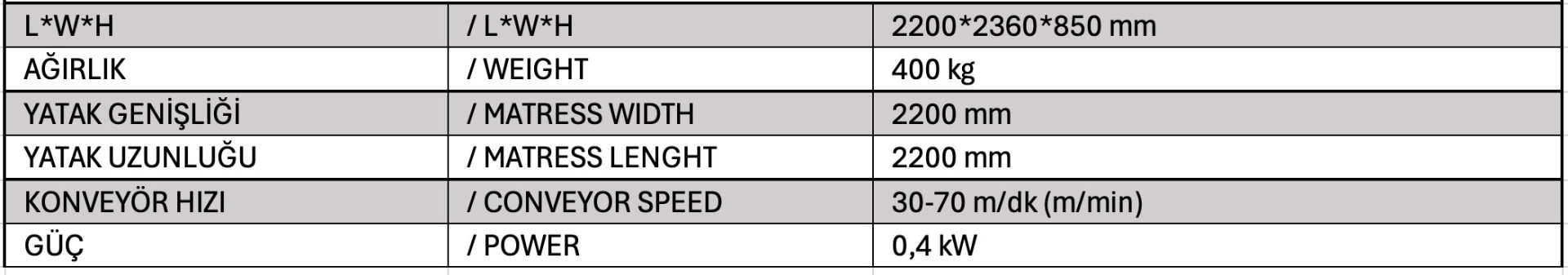

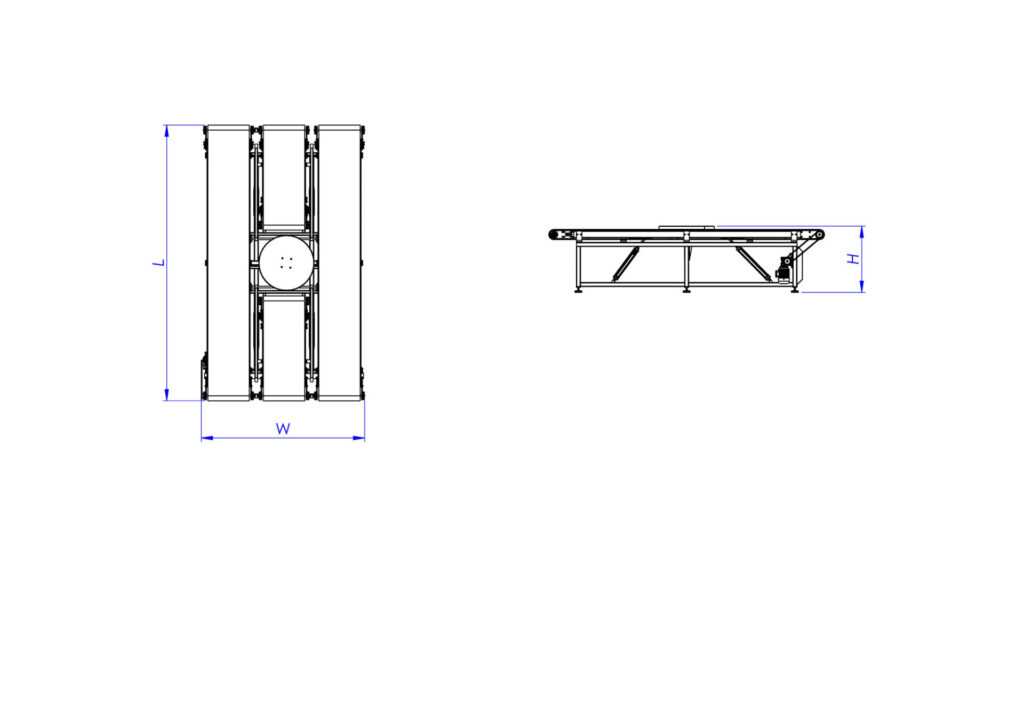

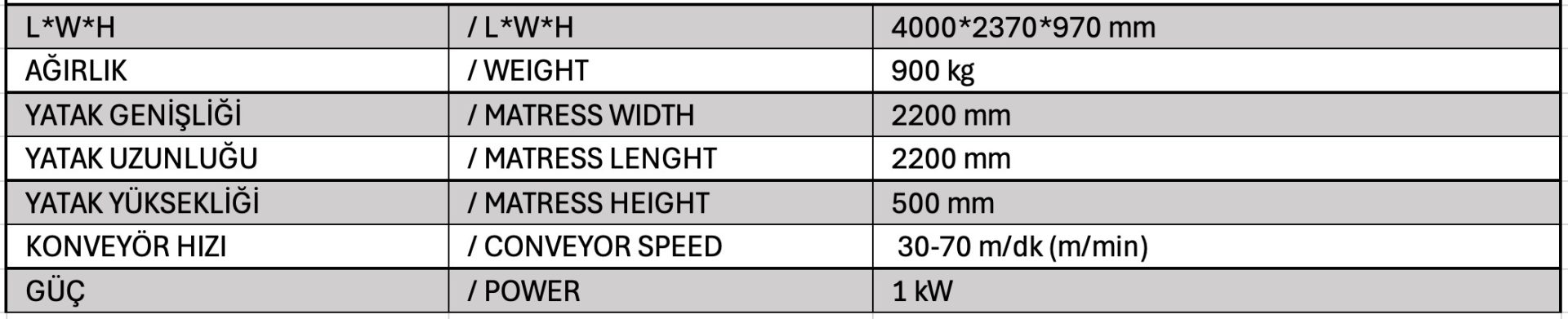

Cross Conveyor

The Cross Conveyor is a specific type of conveyor used to guide finished or semi-finished mattresses along the production line. It is available with roller and PVC belt options. The design of this conveyor prioritizes flexibility and ergonomic principles, ensuring the seamless guidance of mattresses of varying sizes and weights. The Cross Conveyor serves a multitude of industries, including Bedding, Foam, Furniture. This conveyor system contributes to increased production efficiency by allowing you control over product direction, thus optimizing your production flow.

The Cross Conveyor is a specific type of conveyor used to guide finished or semi-finished mattresses along the production line. It is available with roller and PVC belt options. The design of this conveyor prioritizes flexibility and ergonomic principles, ensuring the seamless guidance of mattresses of varying sizes and weights. The Cross Conveyor serves a multitude of industries, including Bedding, Foam, Furniture. This conveyor system contributes to increased production efficiency by allowing you control over product direction, thus optimizing your production flow.

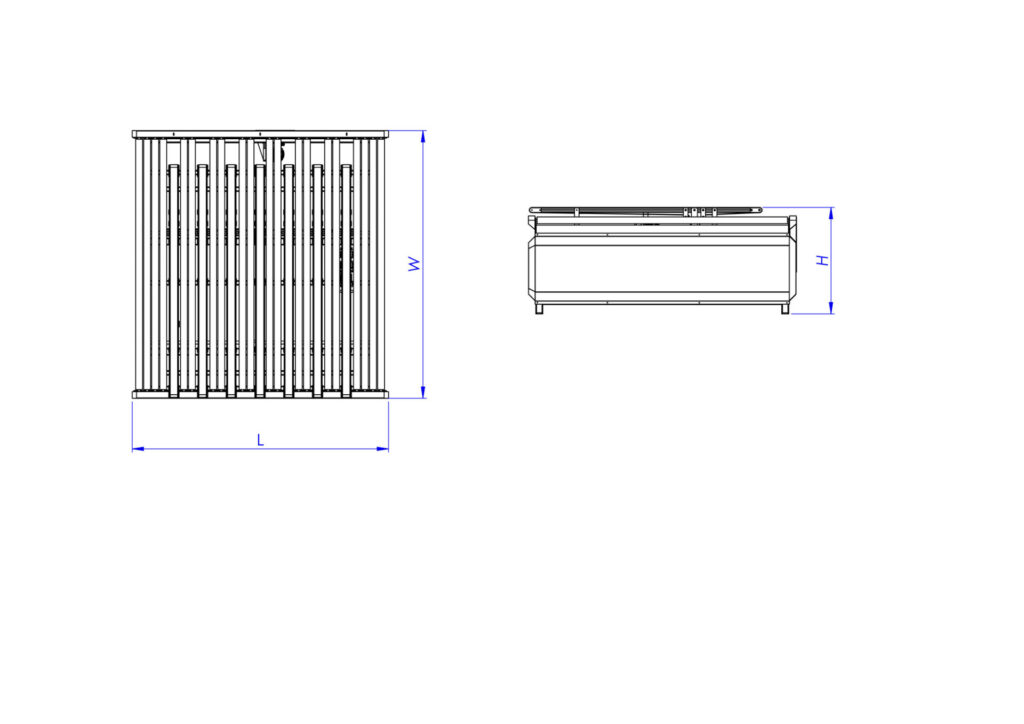

Standart Conveyor

We have developed a fully automatic system equipped with a PLC controller. Within this system, the conveyor is capable of movement in two directions. It features an automatic stop mechanism when the bed is removed. Furthermore, we’ve included an option for user control via the pass mode, enabling manipulation of the conveyor through two pedals on either side. In case of an emergency, the system can be rapidly halted using the emergency stop buttons located on both sides. This design ensures both safety and efficiency in our conveyor system.

We have developed a fully automatic system equipped with a PLC controller. Within this system, the conveyor is capable of movement in two directions. It features an automatic stop mechanism when the bed is removed. Furthermore, we’ve included an option for user control via the pass mode, enabling manipulation of the conveyor through two pedals on either side. In case of an emergency, the system can be rapidly halted using the emergency stop buttons located on both sides. This design ensures both safety and efficiency in our conveyor system.